Product Description:

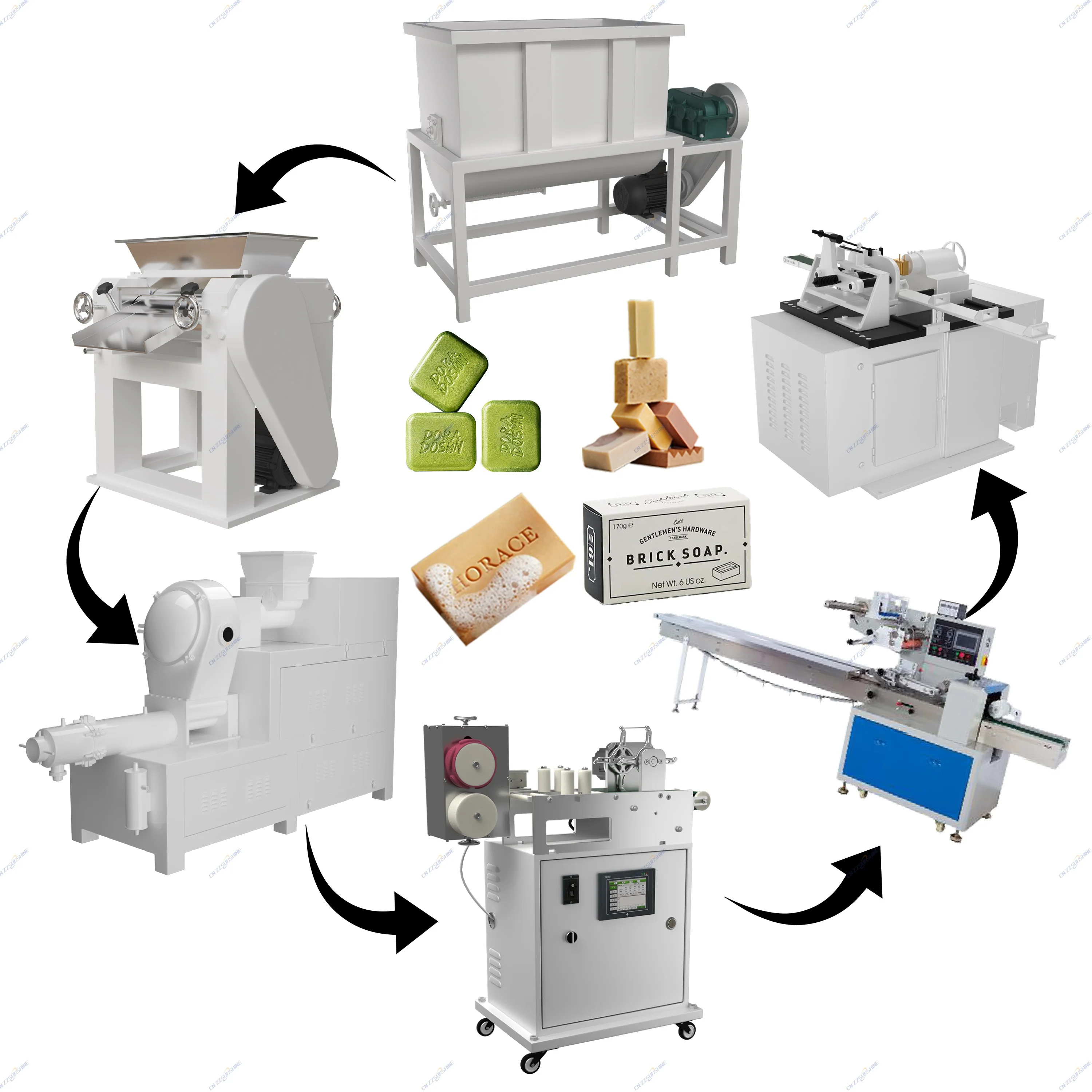

The soap automatic production line is a kind of automatic production equipment, which can complete a series of production processes such as soap ingredients, mixing, molding, cutting, packaging, etc. The equipment mainly consists of multiple parts such as feeding system, mixing system, tablet pressing system, cutting system, packaging system, etc. In the soap production process, the feeding system automatically inputs the required raw materials into the mixing system, and after mixing and stirring, they enter the tablet pressing system for molding. Then, they are cut into soap blocks by the cutting system, and finally packaged by the packaging system.

Advantages:

FAQ:

1.Soap production process?

Basically, the soap production need 2 steps:

a, using all kinds of oil/fast as material to produce semi-finished soap noodle;

b, using semi-product soap noodle to produce end bar soap.

2.What is the kinds of the soaps?

For convenience, we separate the soap into two kinds, toilet soap for washing hand&taking bath, herbal soap, hotel soap,antiseptic soap are included;

The second kind is laundry soap for washing clothes, etc.

3.What kind of oil is suitable for soap production?

All kinds of vegetable oil and animal fats are usable, palm oil, cotton seed oil, tallow oil, coconut oil, sunflower oil, etc.

4.What is the formula?

Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market’s request is available after confirmation of order.

5. How can we guarantee quality?

We will conduct machine testing before shipment to ensure normal operation and provide videos and manuals.Remote video factory and machine inspections are available, and on-site inspections are welcome.

6.What can you buy from us?

Soap Making Machine,Toilet Soap Production Line,Laundry Soap Making Machine,Packing Machine,Bicolor Soap/Tricolor Soap Production Line,Oil Press Machine

7.Why should you buy from us not from other suppliers?

Zhengzhou Sunshine Machinery Equipment Co,.Ltd is a professional corporation devoted herself to research, development, and manufacturing of all kind of soap machinery and equipment. The corporation owned a creative design and manufacturing team. We have CE certificate, national credit certificate, and factory certification for strength,Welcome to visit our factory.