Machine Information

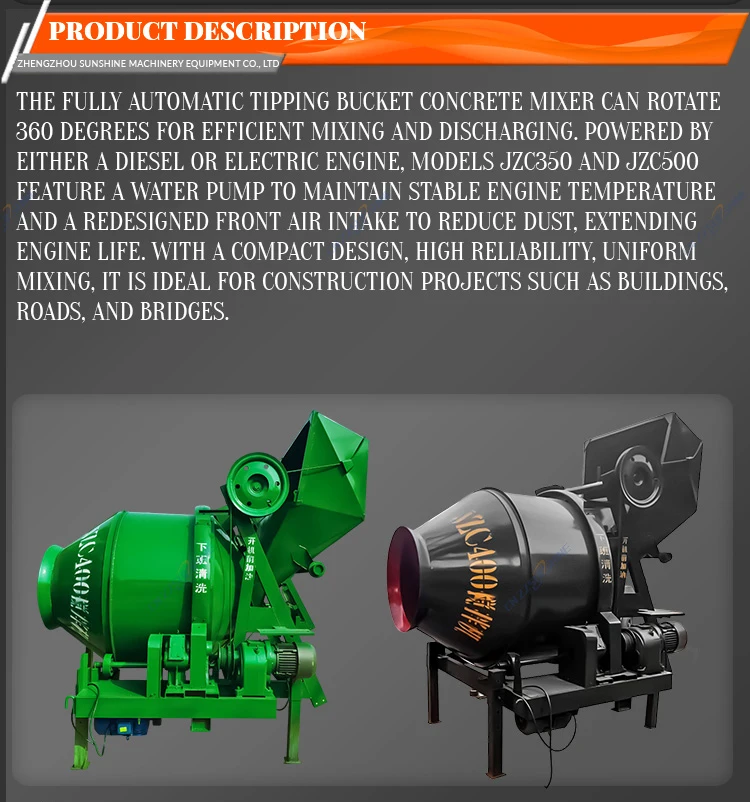

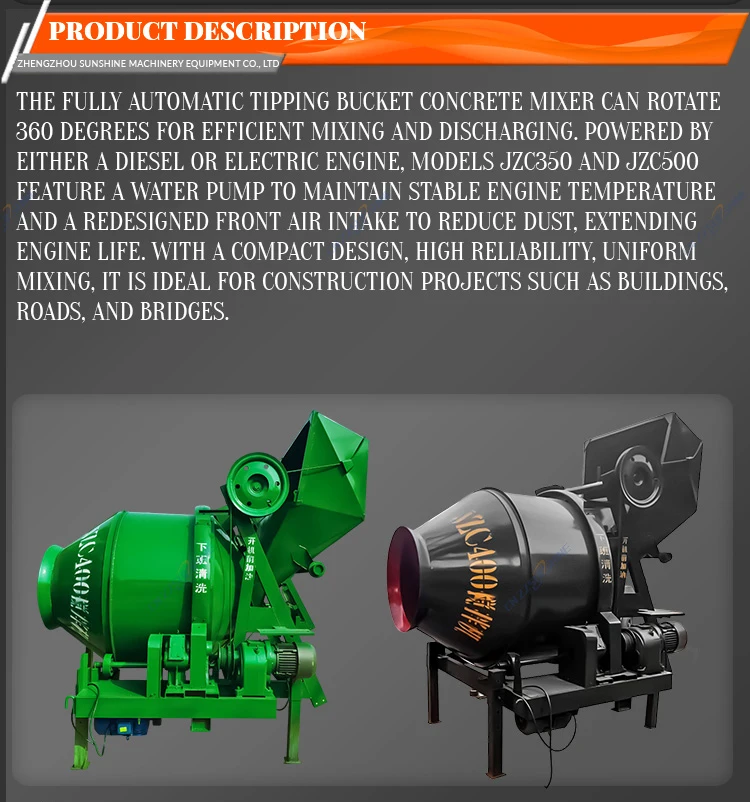

The dump bucket cement mixer is mainly divided into two types: mobile and fixed. The JZC series is the representative model, covering JZC250, 350, 500, 750 and other models. JZC750 is a fixed type, while the rest are mobile. Some models can be combined with batching units to form a simple mixing plant.

Self falling mixer: When in use, the mixing drum rotates around its horizontal axis, and the material added to the mixing drum is lifted to a certain height by the blades and then falls by its own weight. This continuous movement achieves uniform mixing.

Forced mixer: It mainly consists of two horizontally connected circular groove mixing drum, two mixing shafts and rotating mechanisms that rotate in opposite directions. Several sets of mixing blades are installed on the two shafts, which are staggered by a certain space in front, back up and down, so that the concrete mixture is mixed in rotation in the two mixing drums. On the one hand, the bottom and middle of the mixing drum are flipped upwards, and on the other hand, the mixture is pushed forward and backward along the axis, so that the mixture is quickly and evenly mixed.

Applicable scenarios: Widely used in construction sites, road and bridge engineering, small and medium-sized concrete component factories, especially suitable for scenarios that require frequent mobile operations.

The mixing system of a concrete mixer mainly consists of a mixing blade, mixing blades, feed inlet, discharge outlet, etc. A mixing container is a cylindrical container that can hold a certain amount of raw material. The mixing blade is a component fixed inside the mixing blade, which can be driven by an electric motor to achieve sufficient mixing effect of the concretes inside the mixing blade. At the same time, the mixing system is also equipped with a tipping devide to pour out the mixed concrete.

The working principle of the mixing system of a concrete mixer is to add raw materials such as cement, sand, and stones into the mixing balde through the feeding port, start the motor, and start the mixing blades to rotate. The rotation of the stirring blades can thoroughly mix the raw materials inside the stirring blade. When the mixed concrete reaches a certain level, it is poured out through a tipping device.

The working principle of a dump bucket cement mixer is similar to that of a general cement mixer, mainly mixing and blending materials through a mixing system. Specifically, the dump cement mixer may adopt a self falling or forced mixing principle, depending on its design and application requirements. The dump bucket design makes pouring concrete more convenient and improves construction efficiency.

Safety Features

| Emergency Stop Button, Safety Lock

|

|---|

Advantages

| Easy Operate/Stable/Labor Saving/High Efficiency

|

Types

| Dump Concrete Mixing Mixer

|

Mixing Capacity

| 250-499L

|

Driven Method

| Electric Driven

|

Producing Time

| 15 Working Days

|

Company Introduction

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

Certification

Client's Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.

![[Demo Data]The Top Modern Holiday Gifts for the Design Lover in Your Life2](http://holuo.cn-gd.ufileos.com/hkcms/static/module/index/default/img/new2.jpg)