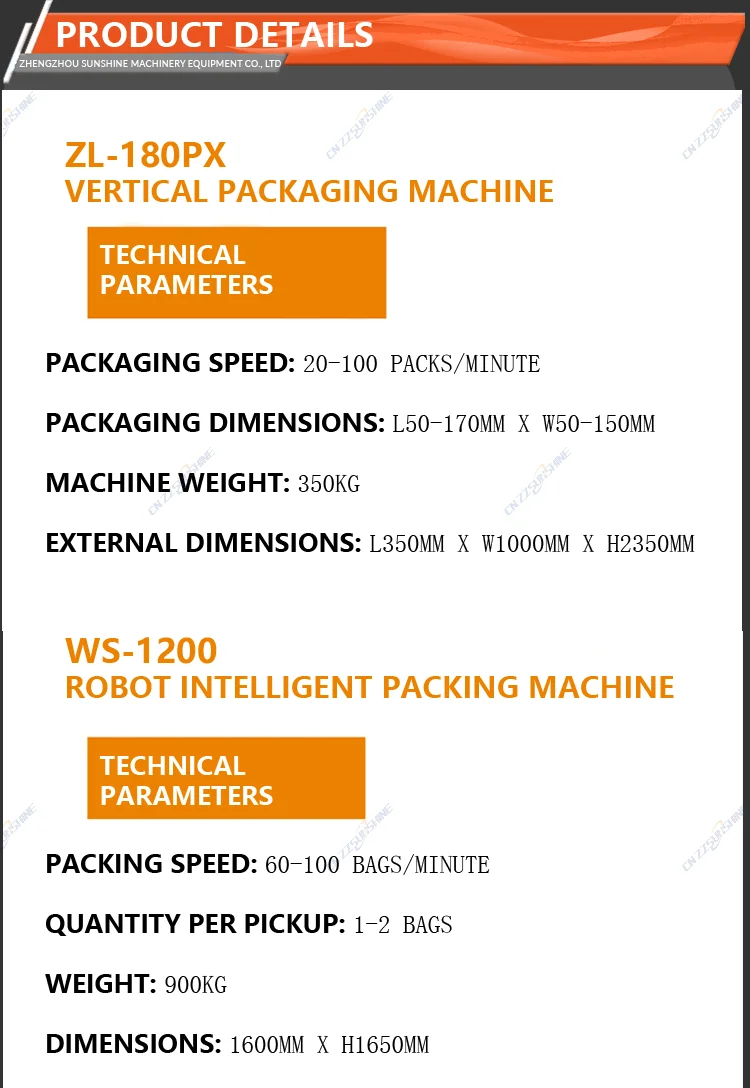

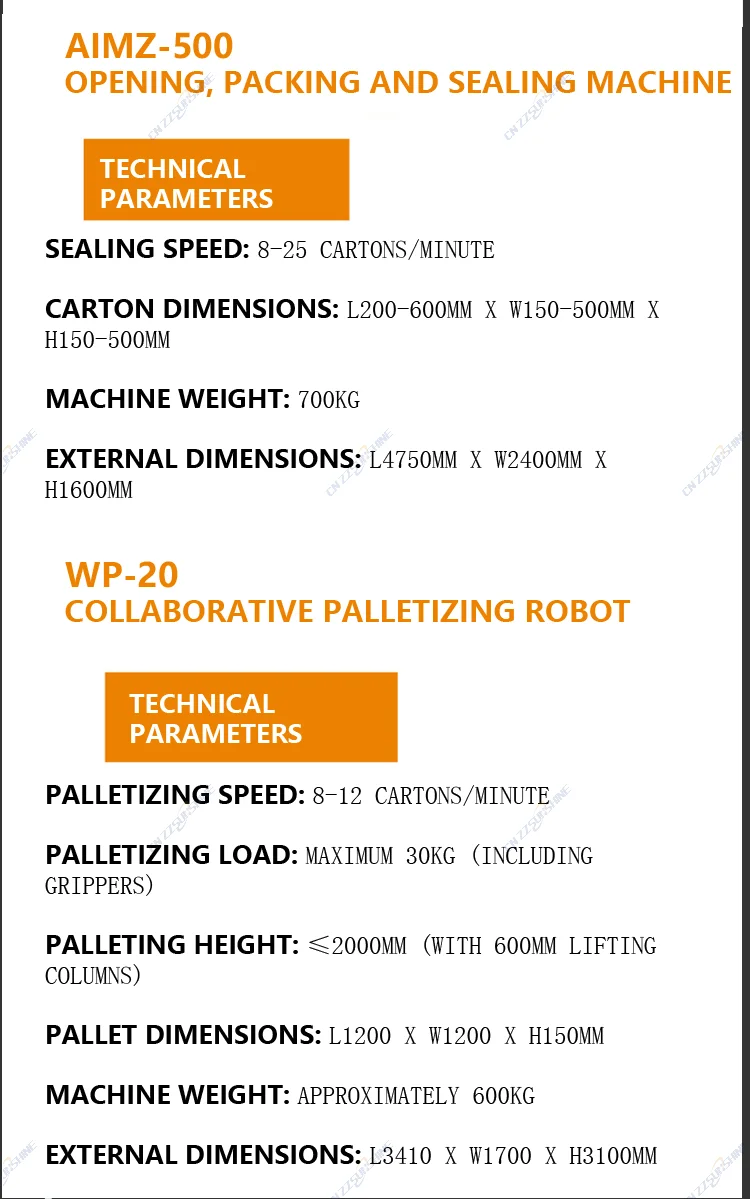

Whole Complete Packaging Palletizing Line

Machine Introduction

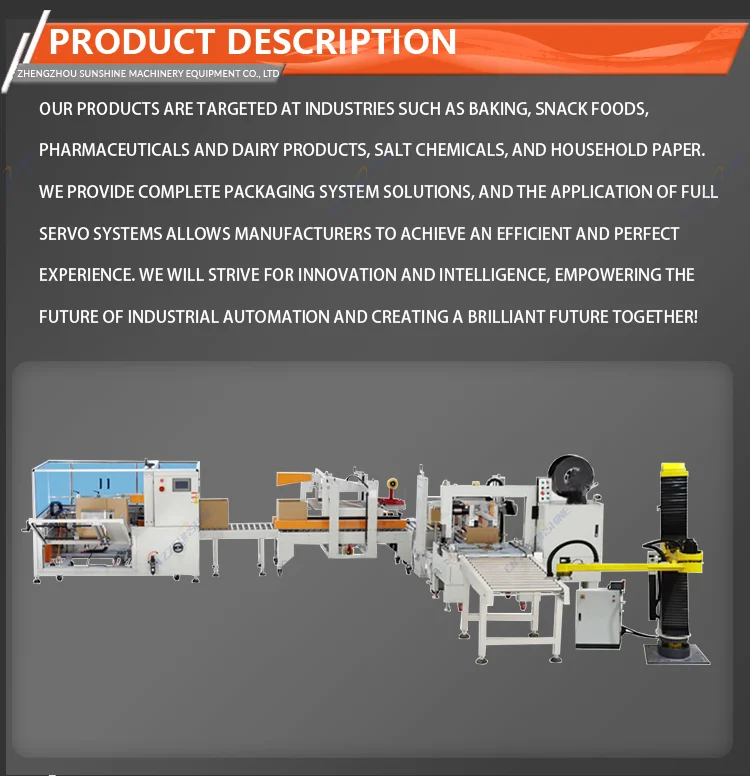

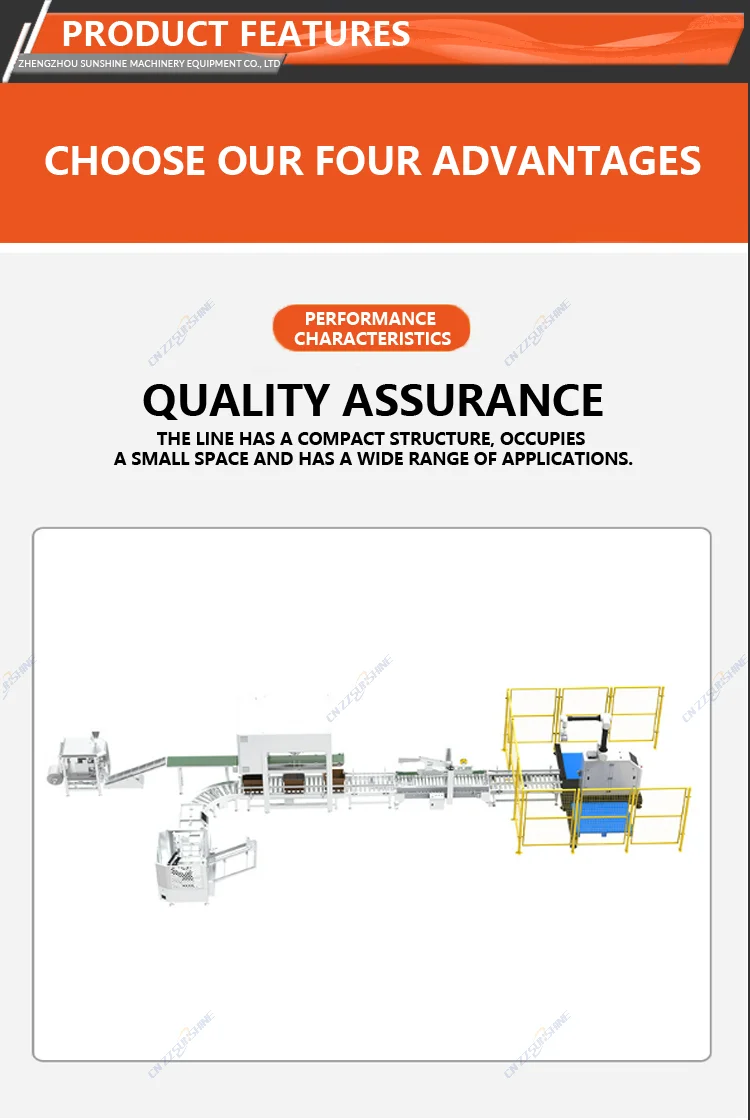

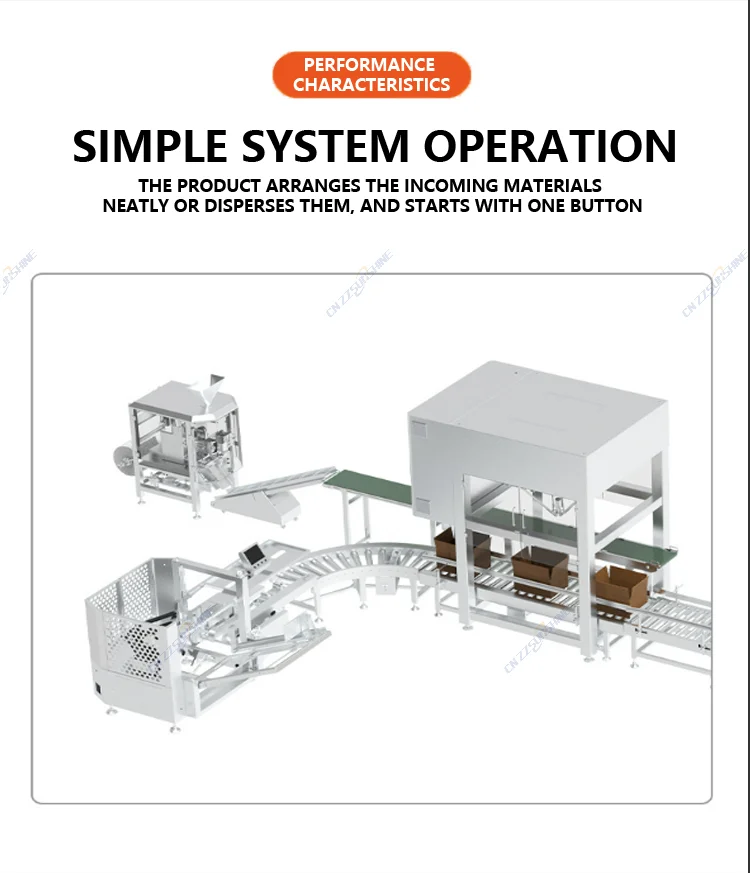

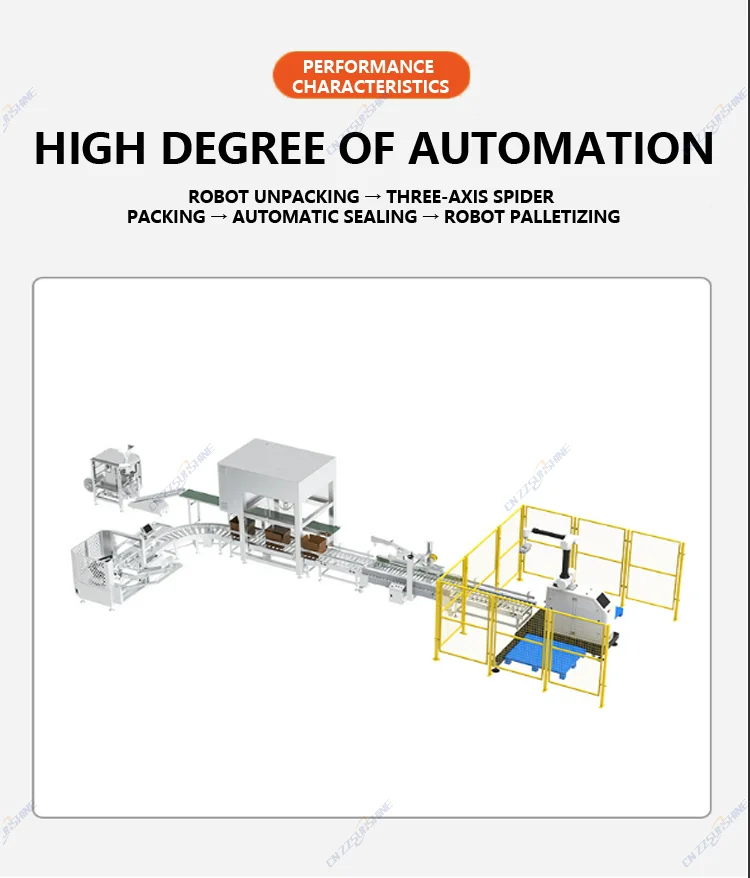

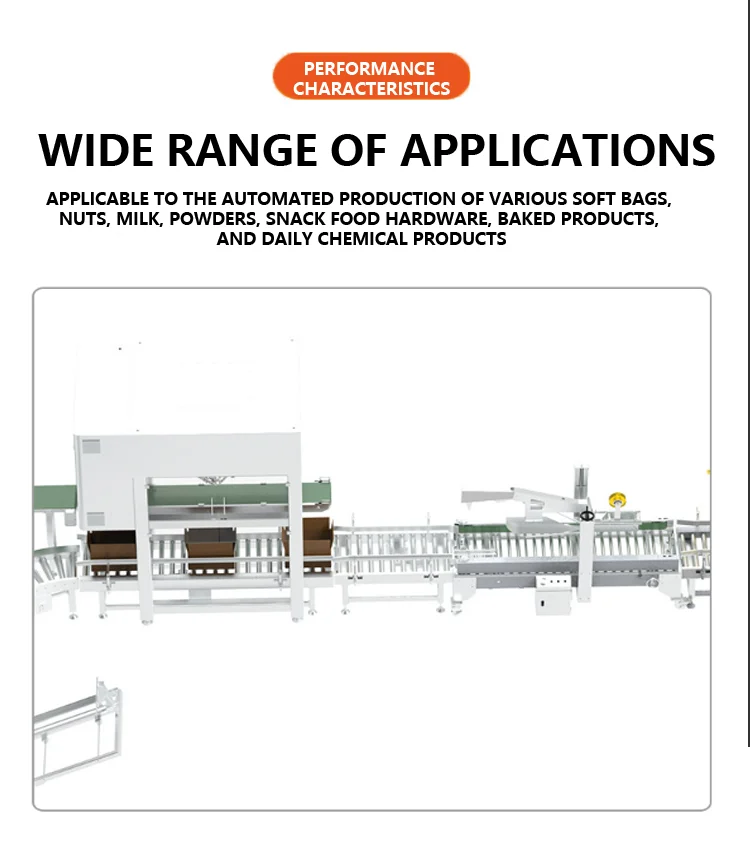

The unboxing, sealing, packaging, and palletizing production line is an automated packaging production line that integrates unboxing, sealing, packaging, and palletizing.

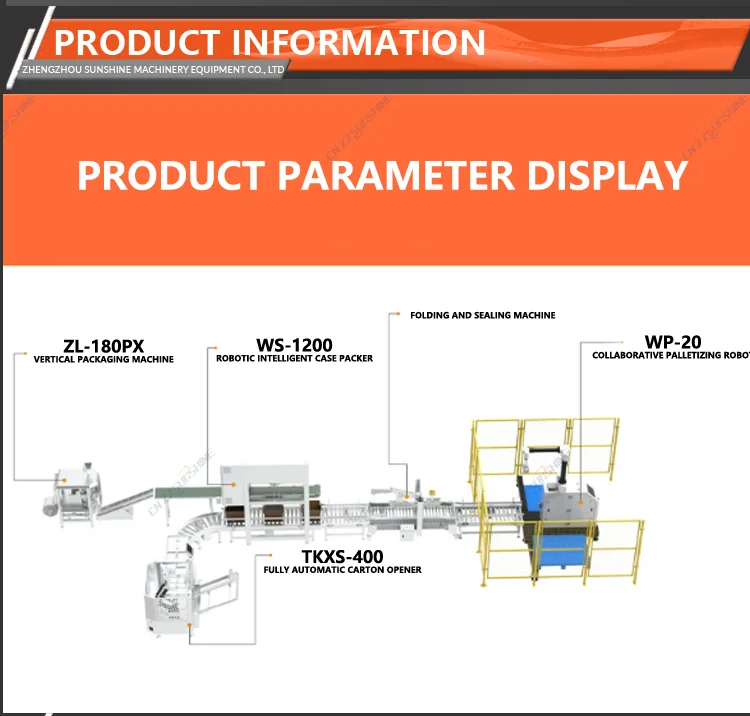

This assembly line is usually composed of equipment such as unboxing machines, sealing machines, packaging machines, palletizing machines (or mechanical arms), etc. It is suitable for the later packaging processes in industries such as beer, food, electronics, and chemical. It can handle materials such as cardboard boxes, plastic boxes, and pallets, and achieve unmanned operations from automatic unboxing and sealing of cardboard boxes, I-shaped sealing, packaging to automatic palletizing, improving production efficiency and reducing labor costs. The stacking speed can reach 2-4 layers per minute, with a maximum stacking height of 1600mm (including pallets), and supports customized sizes according to requirements.

The mechanical system of the fully automatic packaging and palletizing production line mainly includes a fully automatic weighing unit, packaging unit, conveyor detection unit, and palletizing unit. The material enters the feeding device of the packaging scale from the self storage hopper, and is fed in two stages of coarse and fine feeding. When the weight of the material in the weighing hopper reaches the final set value, the weighing end sends a stop feeding signal. After all the flying materials in the air fall into the weighing hopper, the weighing cycle ends. At this time, the electronic packaging scale waits for the feeding signal from the bagging machine.

System Composition:Core equipment: automatic weighing and packaging scale, unboxing machine, boxing machine, sealing machine, palletizing robot, conveyor.

Auxiliary systems: control system (programmable controller/industrial computer), safety protection device (emergency stop button, sensor), dust removal equipment, inkjet printer, etc.

After being packaged by an automatic packaging machine, the materials are sorted, turned, and accelerated through a conveyor line, and loaded into cardboard boxes according to preset quantities. After sealing the boxes, they are stacked by a palletizing robot according to rules, and finally processed by a winding machine before being stored or loaded onto trucks.

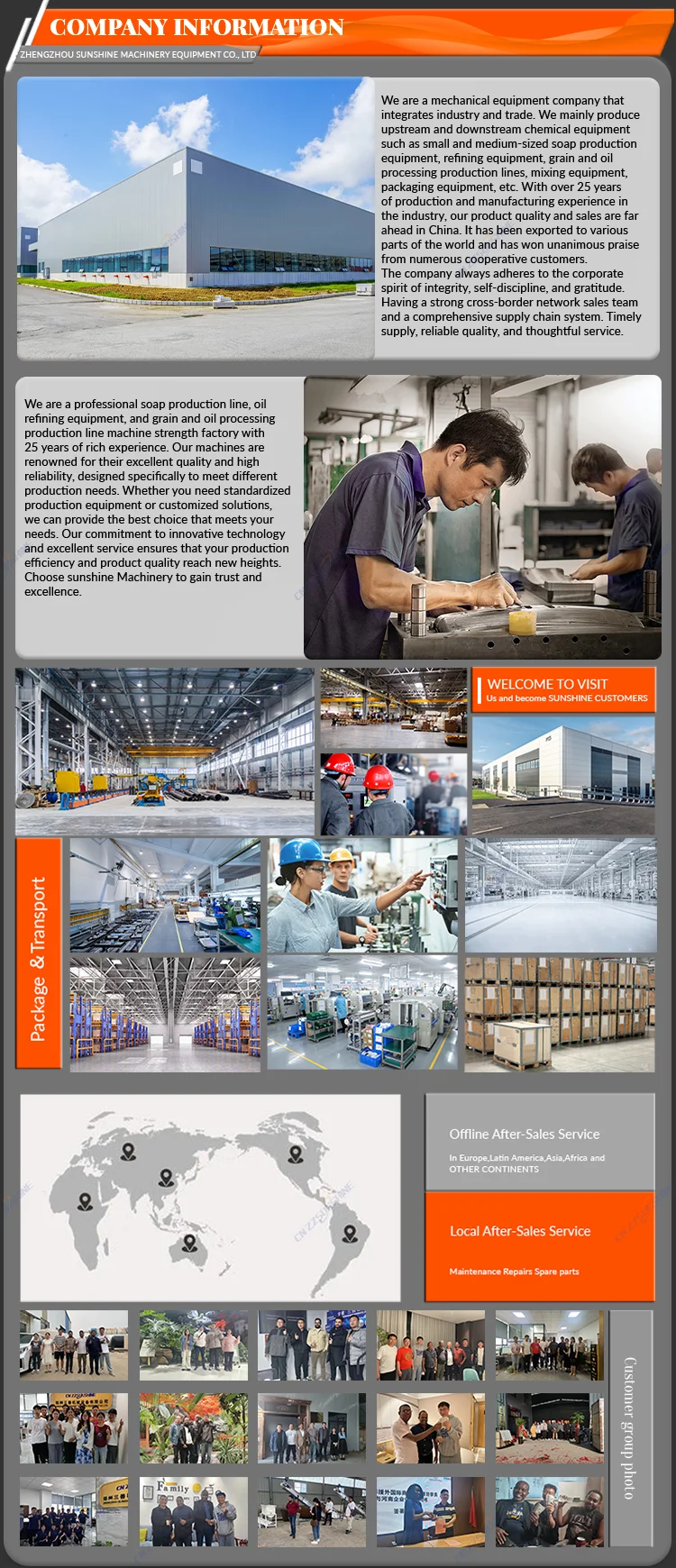

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

Certification

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.

A total of 1 page 1 data

![[Demo Data]The Top Modern Holiday Gifts for the Design Lover in Your Life2](http://holuo.cn-gd.ufileos.com/hkcms/static/module/index/default/img/new2.jpg)