Full Automatic Auger Filling Machine for Milk Powder Durable Flour Sugar and Salt Powder Filling Bottling Machine Finishing Line

Production Description:

The system employs a dual-head feeding mechanism and a split hopper, ensuring high precision while eliminating the inconvenience of cleaning associated with rotary feeding systems.It primarily performs high-precision filling and metering.

1. The machine can automatically complete the processes of mixing, metering, filling and so on.

2. The materials can be put into containers such as bottles, cans, barrels, boxes, bags, etc.

3. The machine parameters are set through the touch screen, and the operation is simple and easy to use.

4. Intelligent PLC control, stable machine operation and high work efficiency.

5. Small footprint, suitable for factories, shops, bars and other places.,extra accuracy

* The powder packing machine is a machine with mechanical, electrical, optical, instrument in whole one, single- chip control,with functions of automatic quantitative, automatic filling, automatic adjustment of measurement errors and so on

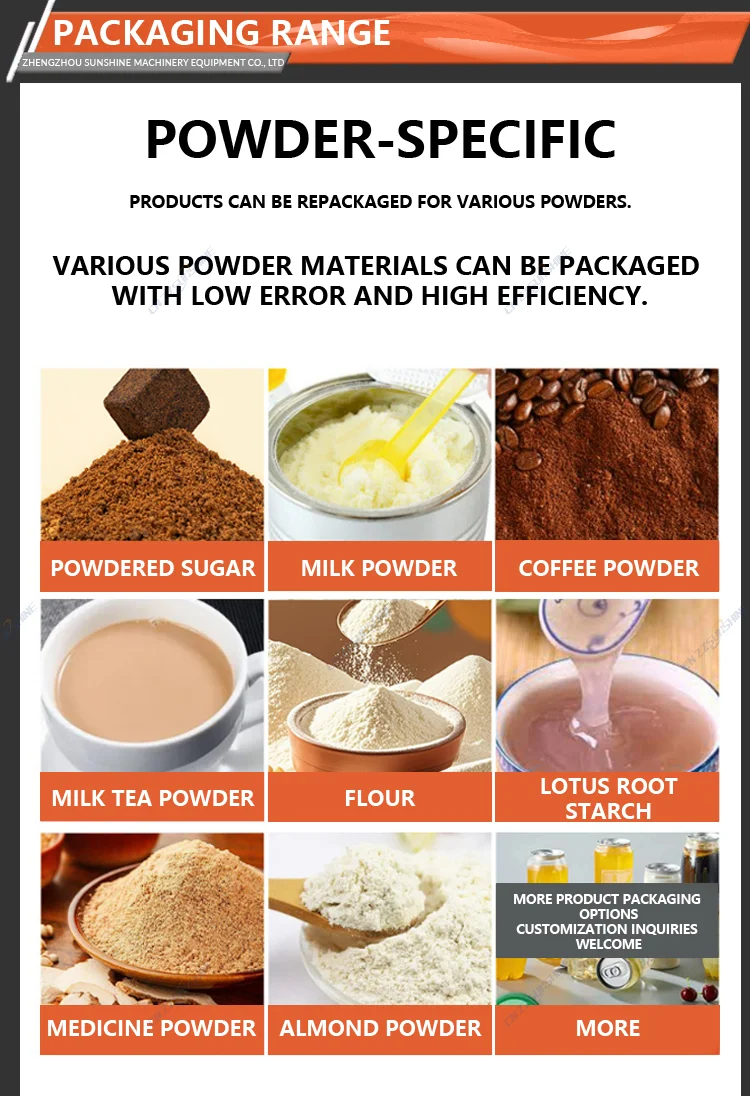

* Working principle: Auger volume or Auger weight

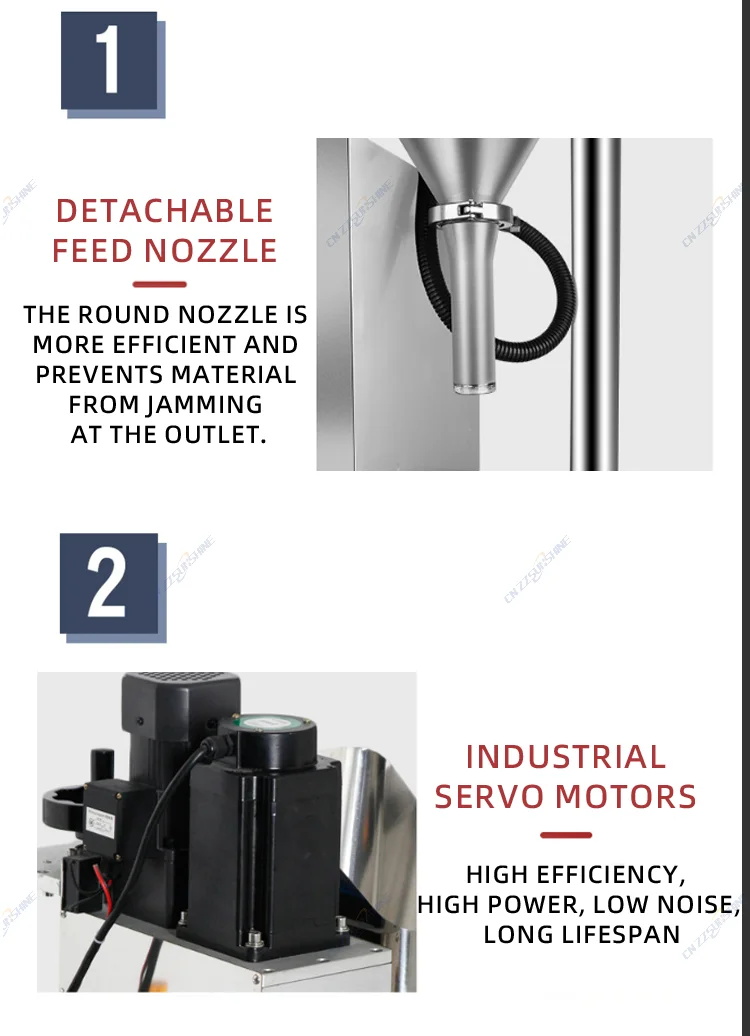

* Fast speed: adopting spiral blanking, the light- control technology

* High precision: adopting the servo motor and electronic weighing technology(filling error 1-2g)

* Applicable to a wide range: all kinds of fluidity powder

* Suitable for bags, cans, bottles and other containers powder packing

* The error caused by the proportion of materials and materials level changed can be automatically tracked

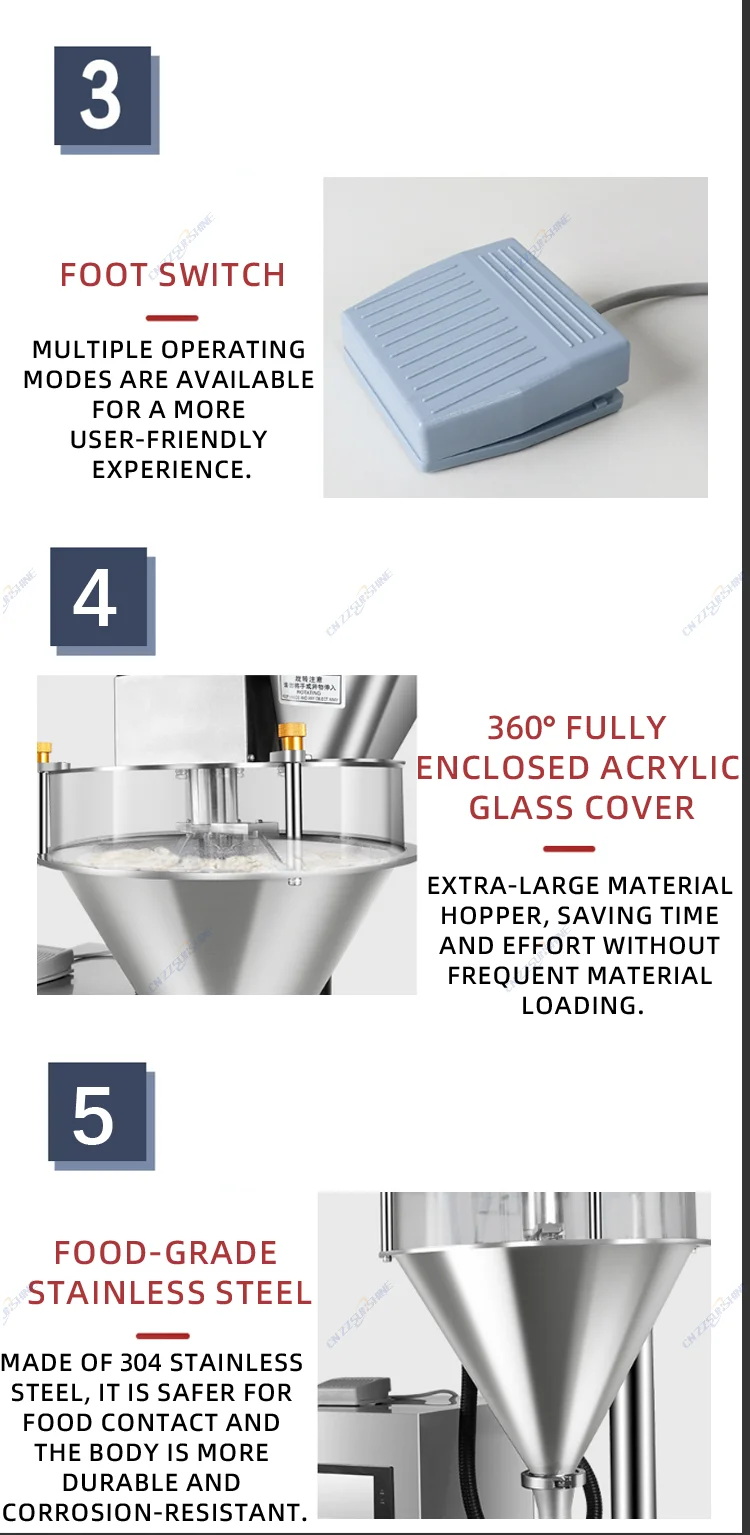

* Filling machine hopper capacity is 50L which is Openable visibility structure design,Not only is it easy to clean, but the concentricity does not need to be adjusted. It is very convenient to adjust the relative position of the stirring and the screw to achieve the best use effect.

* Photoelectric- switch control, only the need of manual bagging. The pocket is clean, easy to seal.

* Parts contacted with the material are made of stainless steel, easy to clean to prevent cross- contamination

* The machine can be configured for auger feeding device, which working controlled by the sensor.

FAQ:

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.

![[Demo Data]The Top Modern Holiday Gifts for the Design Lover in Your Life2](http://holuo.cn-gd.ufileos.com/hkcms/static/module/index/default/img/new2.jpg)