Paper Box Packaging Machine

The paper box packaging machine is an efficient, precise, and environmentally friendly automated equipment widely used in modern industrial production lines. It achieves a series of processes such as forming, filling, sealing, labeling, and packaging of paper boxes through automated assembly line operations, significantly improving production efficiency and reducing labor costs.

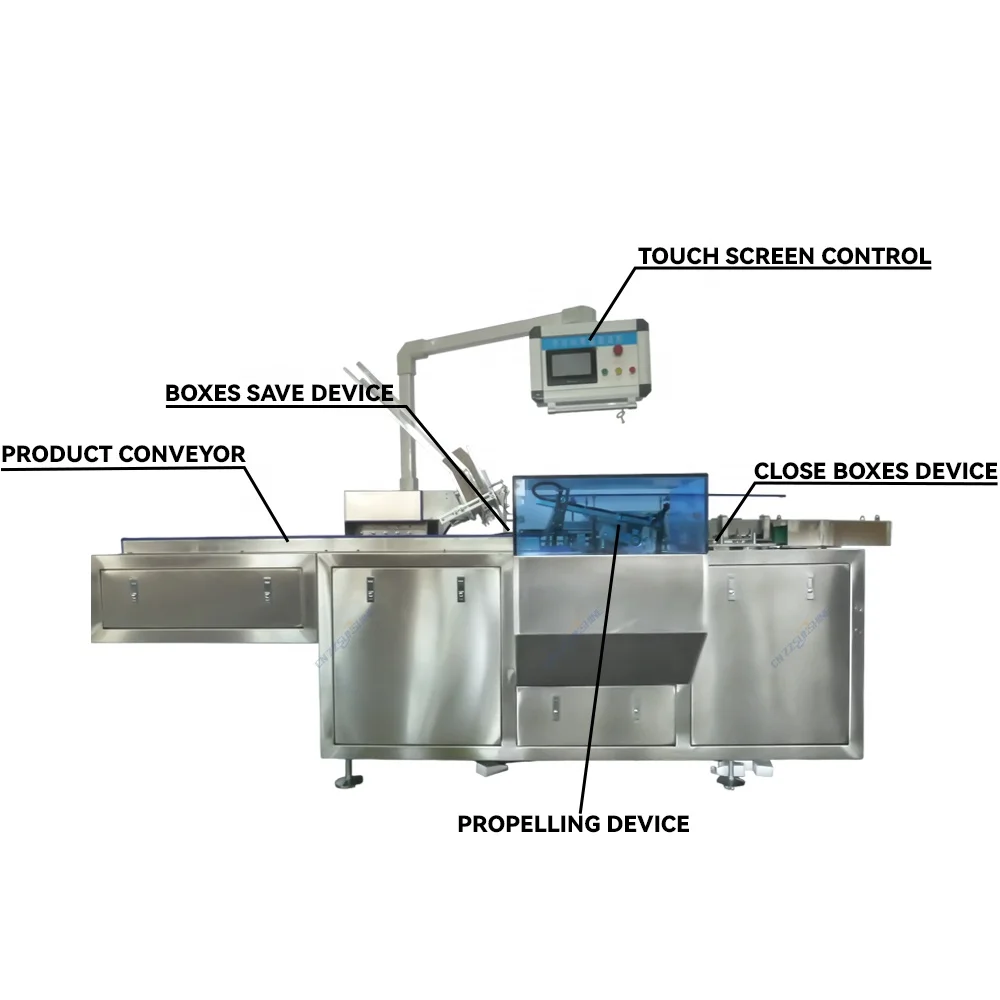

The main working principle of a paper box packaging machine includes several steps: feeding, forming, filling, sealing, and output. Firstly, the cardboard or paper box raw materials are fed into the forming area through an automatic feeding system, and the flat cardboard is folded into a designed three-dimensional paper box structure using molds and pneumatic devices. Subsequently, the filling system places the product into a formed paper box based on its characteristics, and the sealing device ensures the sealing of the paper box. Finally, the packaged product is output through a conveyor belt.

In terms of technical characteristics, modern paper box packaging machines generally adopt PLC control systems or servo control technology to achieve fully automated operation, reduce labor costs, and improve production efficiency. Its precise mechanical design and sensor technology ensure the accurate size, shape, and sealing position of each paper box, with strong adaptability and the ability to quickly adjust to accommodate products of different sizes and weights. In addition, modern paper box packaging machines also pay attention to energy conservation and environmental protection, using low-energy motors and optimized transmission structures to reduce energy consumption.

Characteristic

1.Widely applicable

The paper box packaging machine has a wide range of applications and is suitable for packaging goods of different specifications and types, such as food, medicine, cosmetics, daily necessities, etc. Due to the ease of processing and printing, paper boxes can be easily customized for packaging design based on the characteristics of different products.

2. High degree of automation

Paper box packaging machines usually adopt advanced mechanical and electrical control systems, which can achieve automation and intelligent production. The operator only needs to place the paper box at the feeding device, and the machine can automatically complete the entire packaging process, greatly improving production efficiency.

3. High production efficiency

Paper box packaging machines usually have high production efficiency and can complete the packaging of a large number of goods in a short period of time. Meanwhile, due to the ease of storage and transportation, paper boxes can effectively reduce production costs,

4. High security

Paper box packaging machines are usually equipped with safety protection devices to prevent accidental damage to books during operation. For example, when there are too many or too few cardboard boxes placed, the machine will automatically stop running and sound an alarm. In addition, the paper box packaging machine can also achieve functions such as sealing and labeling, ensuring that the goods are not easily damaged during transportation.

FAQ:

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery. if you need,pls contact 008618530006878