Production Information

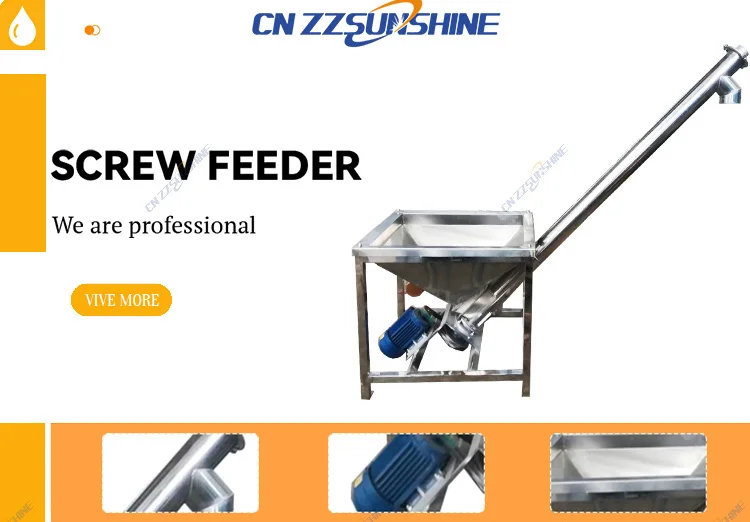

Spiral feeder, also known as automatic feeder, spiral elevator, feeder, conveyor, or transmission feeder, is a type of conveying equipment that does not have a winding traction component. Its main component is a spiral (agitator), and the spiral body rotates in a fixed inclined conveying pipe (or groove) to transport materials.

The spiral drive feeding machine adopts a spiral rod for feeding. After pressing the start switch, the spiral rod rotates and continuously pours the material into the feeding box. The feeding spiral rod will continuously lift the material up to the discharge port. When the spiral shaft rotates, due to the gravity of the material and the frictional force generated with the groove wall, the material can only move forward along the groove bottom of the conveyor under the push of the blades, just like a nut that cannot rotate moves in translation along a rotating screw.

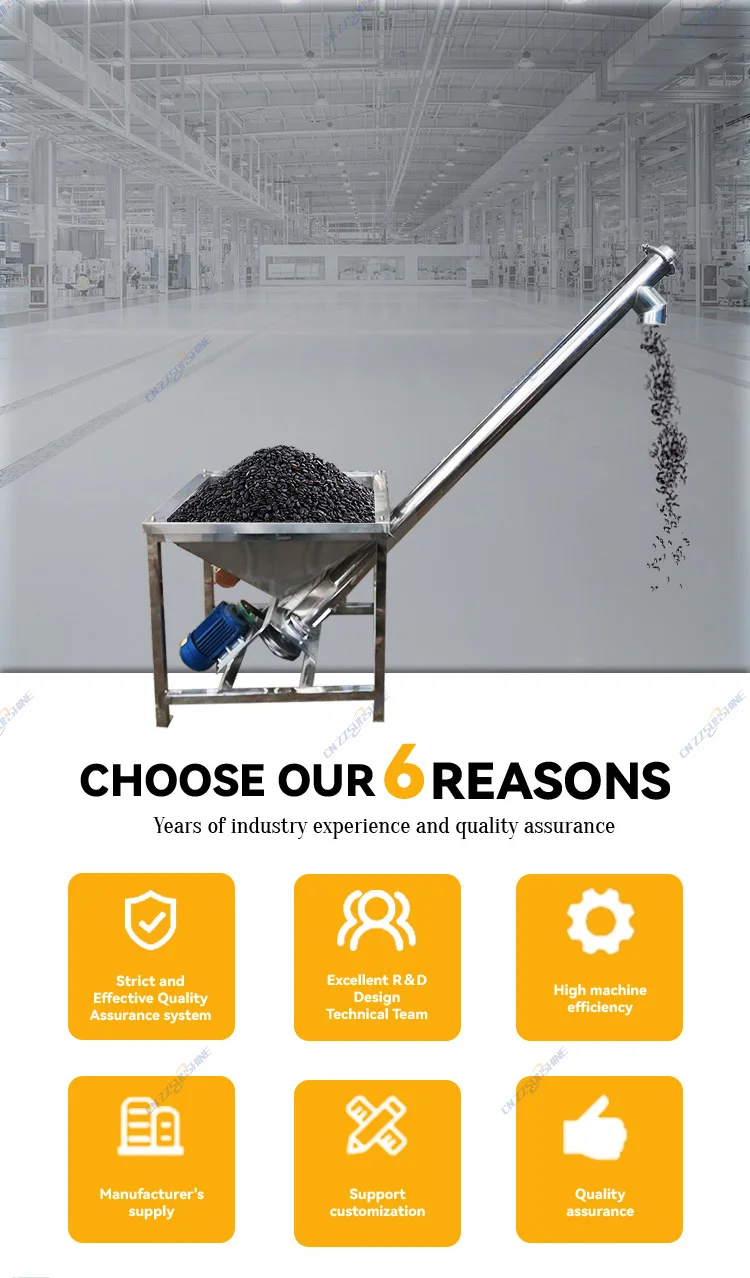

It can be widely used for conveying and feeding powders, granules, and sheets in plastic, pharmaceutical, food, and chemical production processes. It can also be used for the transportation, storage, and loading of bulk grains (such as wheat, corn, soybeans, buckwheat, rice, sorghum, and other agricultural crops), as well as for chemical granules and materials with high hardness that are not easily broken. In addition, it is also suitable for industries such as mining, feed, grain and oil, and construction, and can transport materials such as coal, cement, stones, sand, clay, ore, etc. in powder, granular, and small block forms without or with low grinding properties

| Usage | Building Materials, Chemical Industry, Colliery, Gravel Field, Metallurgy, Mine, Ore-dressing |

|---|---|

| Advantages | Flexible/Easy Install/Easy Operate/Automatic |

| Package Method | Wooden Case |

| Related Machine | Sheller/Oil Press Machine/Frying Machine |

| Types | Flexible Screw Feeder |

| Producing Time | 15 Working Days |

Company Information

Certification

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.