Product Introduction

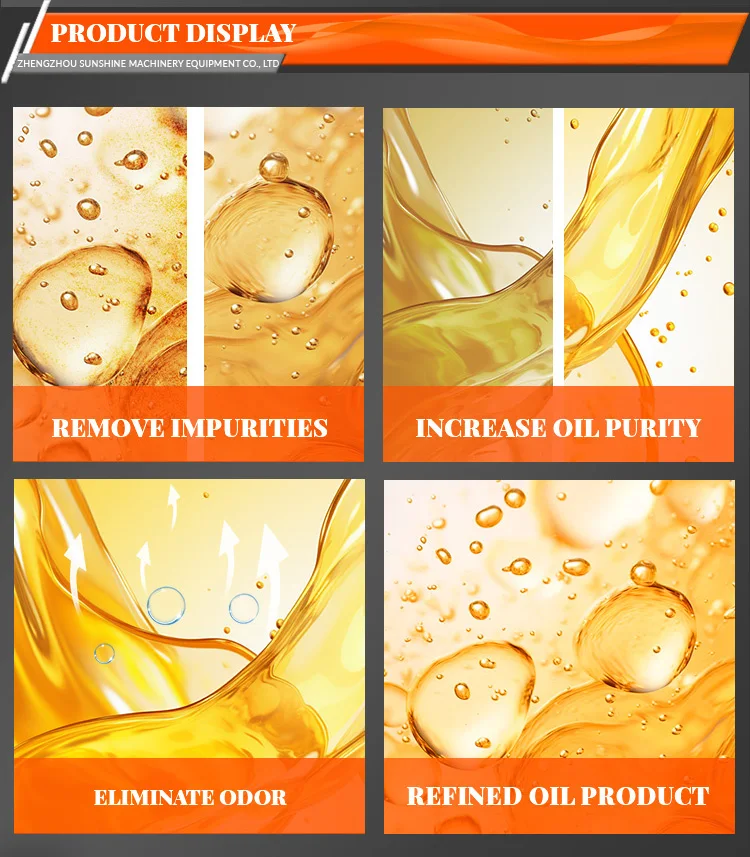

Oil refining refers to a series of processes that remove solid impurities, free fatty acids, phospholipids, colloids, waxes, pigments, odors, and other substances from vegetable oils.

The oil that undergoes filtration, degumming, and deacidification is called semi refined oil. The oil that undergoes decolorization, deodorization, winterization, and dewaxing is called refined oil.

Degumming: The process of removing water-soluble impurities from crude oil using physical, chemical, or physicochemical methods is called degumming. In edible oils and fats, if there is a high content of phospholipids, they are prone to foaming, smoking, and have a foul odor when heated. Additionally, phospholipids oxidize at high temperatures, causing the oil to turn brownish and affecting the flavor of fried foods. Degumming is based on the principle that phospholipids and some proteins dissolve in oil in wastewater, but do not dissolve in oil when they form hydrates with water.

Hot water or steam is added to the crude oil, and the oil is heated and stirred at a temperature of 50 ℃. Then, it is allowed to stand and separate into layers, and the aqueous phase is separated to remove phospholipids and some proteins.

Deacidification: Free fatty acids affect the stability and flavor of oils, and can be removed by neutralization with alkali, also known as deacidification or alkali refining.

Decolorization: Crude oil contains pigments such as chlorophyll and carotenoids. Chlorophyll is a p

hotosensitizer that affects the stability of the oil, while other pigments affect the appearance of the oil and can be removed by adsorbents.

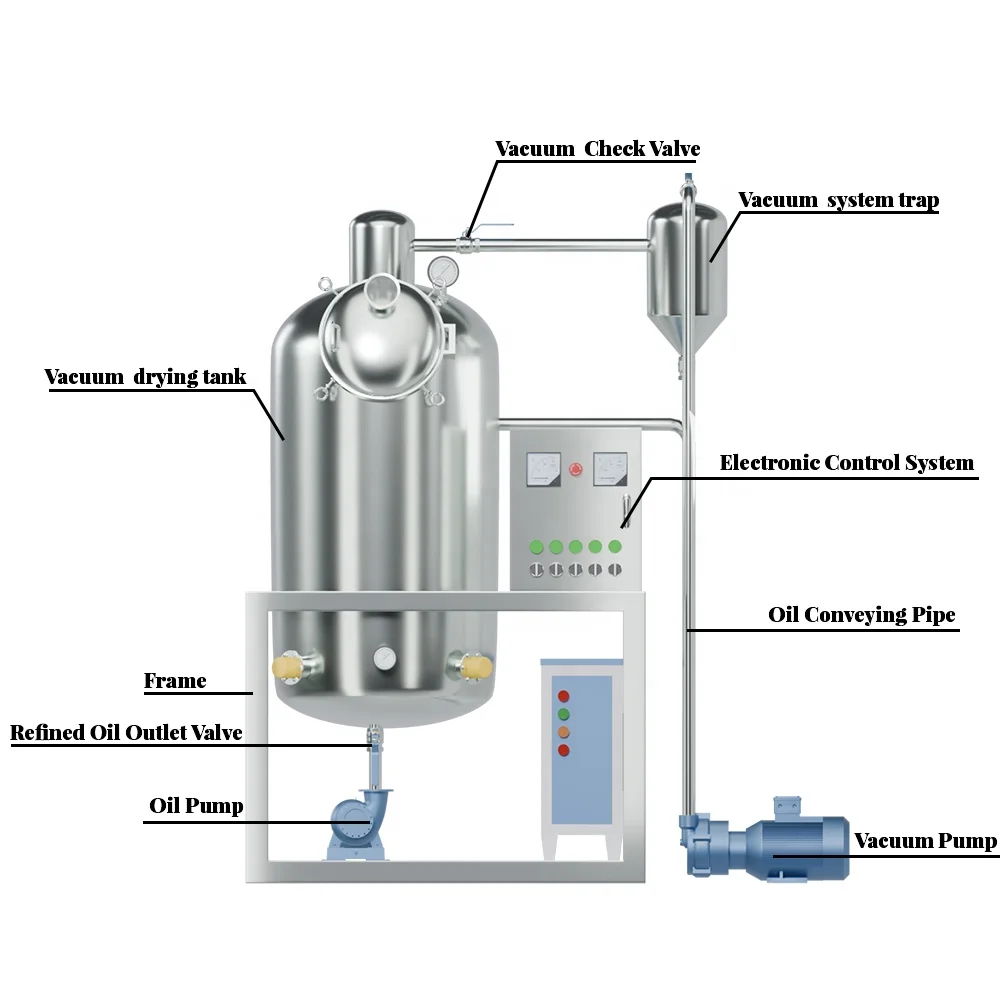

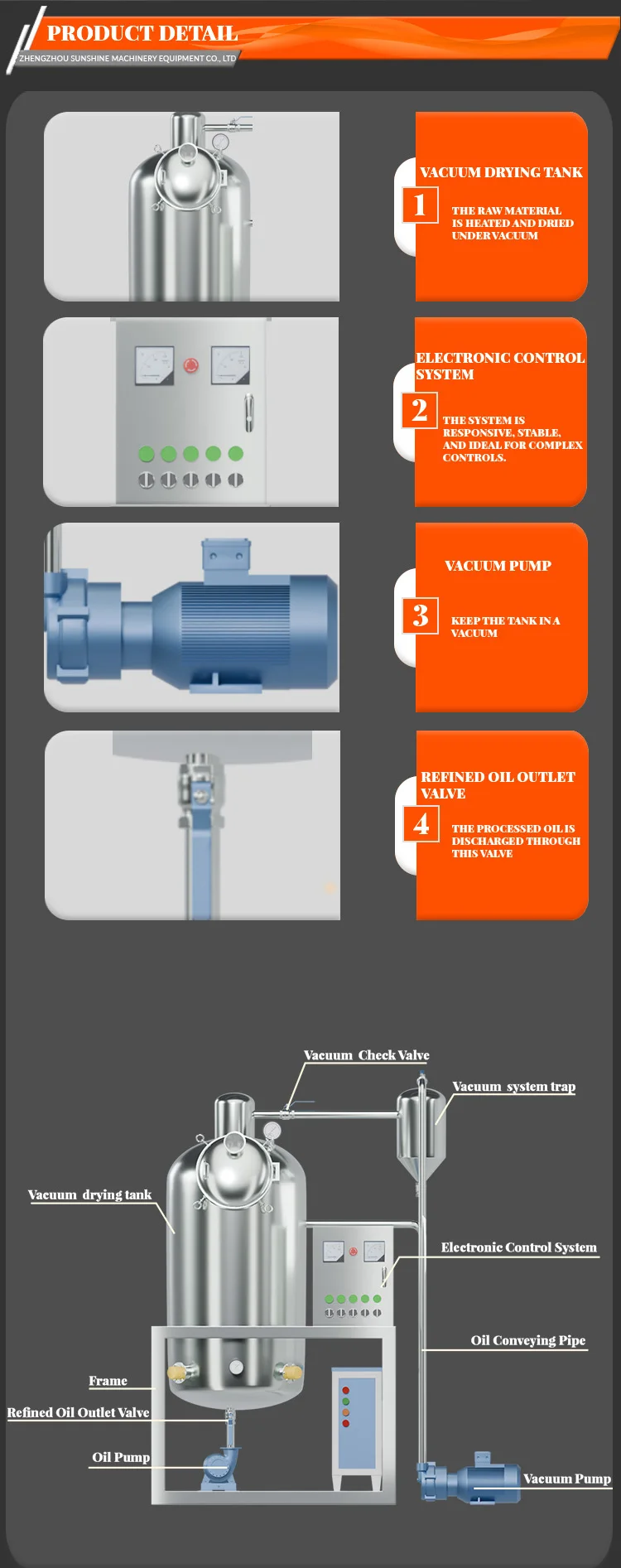

Deodorization: There are some undesirable odor substances in oil, mainly derived from the oxidation products of oil. Adopting the method of vacuum distillation and adding citric acid to chelate excessive metal ions and inhibit oxidation.

Usage

| Oil Refinery/Chemical Materials Mixing/Reactor

|

|---|

Working Hours

| 8 Hours or More

|

Color

| Clients Demand

|

Advantage

| Easy Operate/Widely Used/Stable Reactor

|

Core Part

| Control System/Gear/PLC

|

Package Method

| Wooden Case with Plastic Film

|

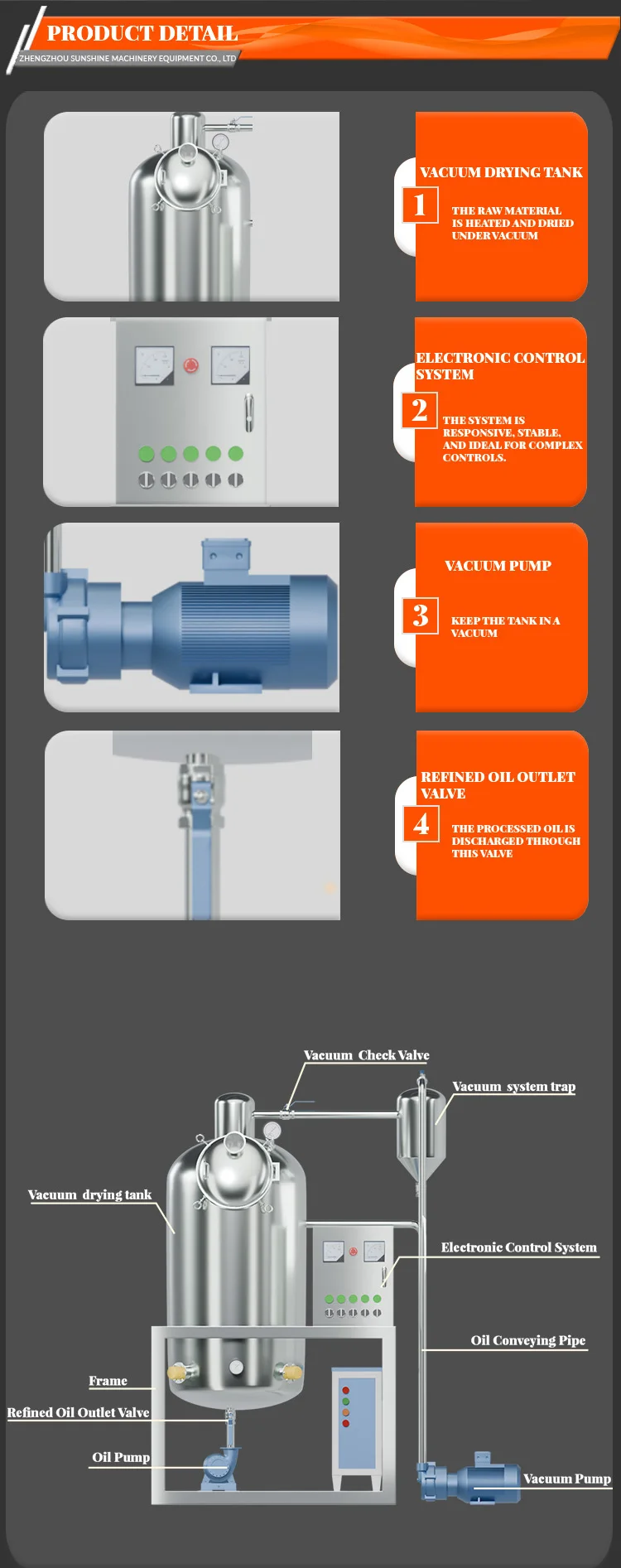

Detail Photo

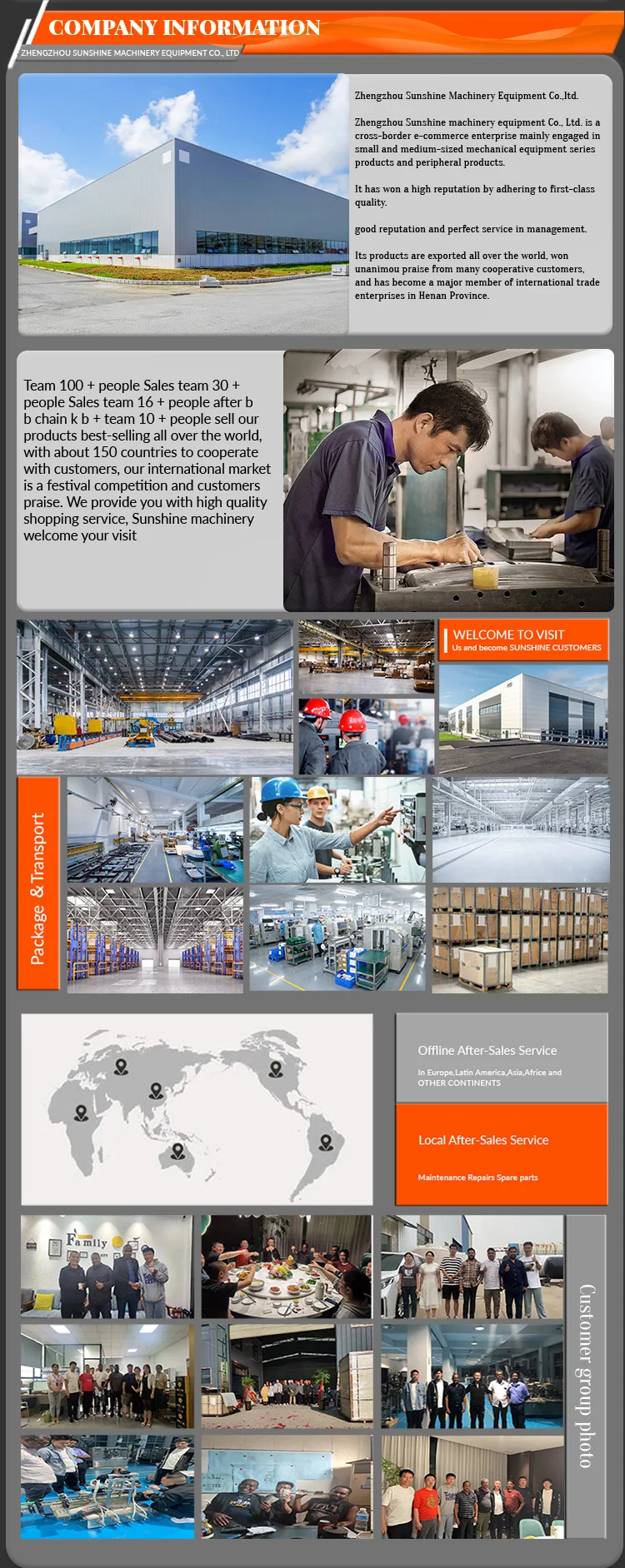

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

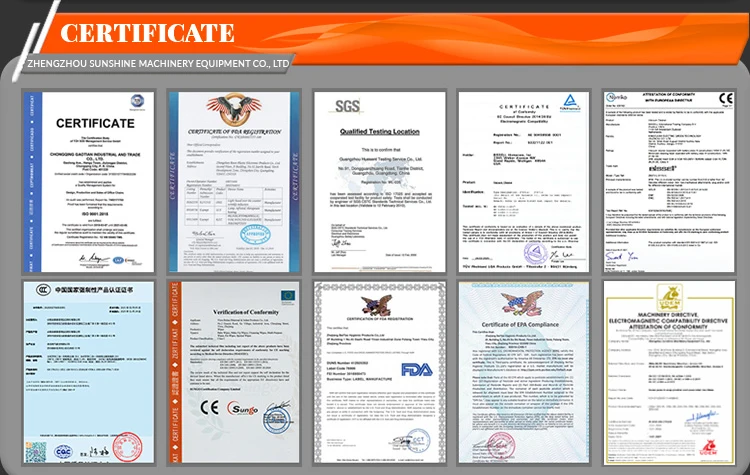

Certification

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.