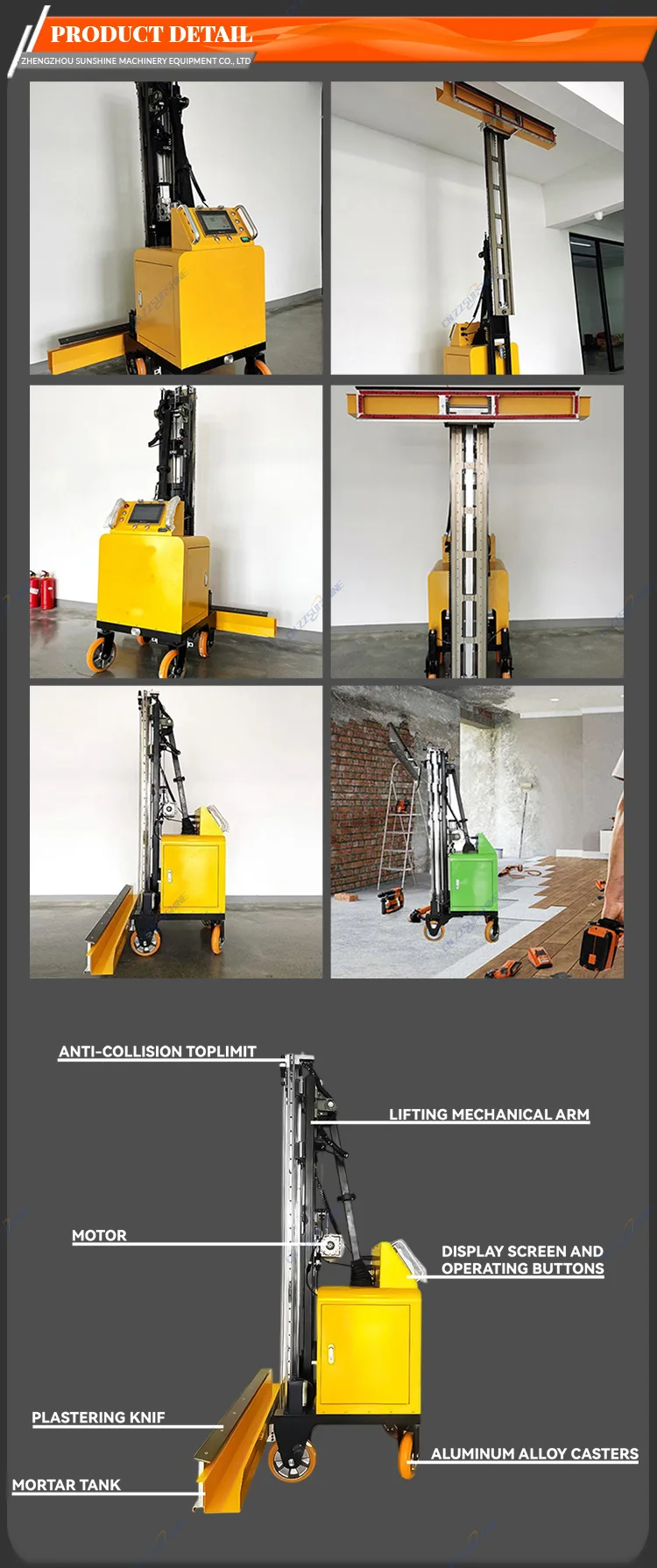

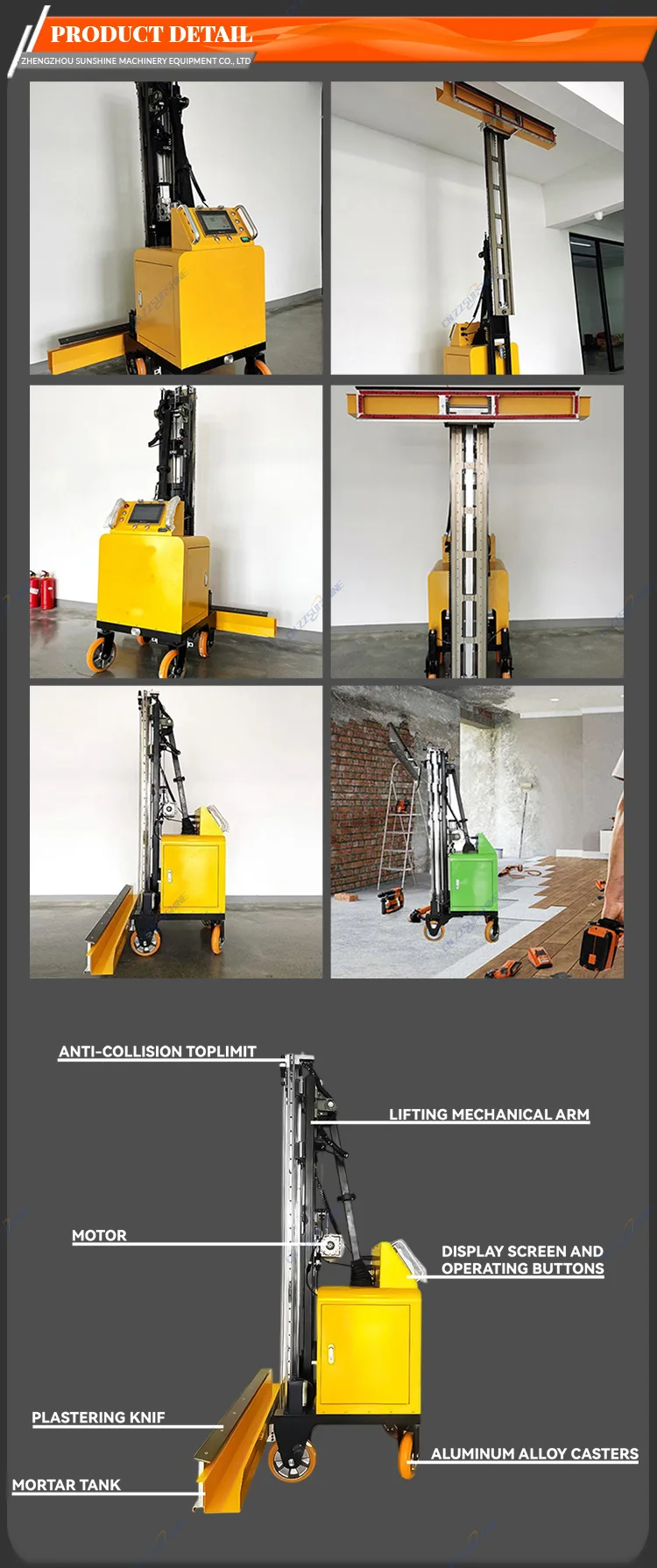

Product Introduction

A mortar coating machine, also known as a mortar spraying machine, is a mechanical device used to evenly apply mortar onto walls or other substrates.

Material preparation: Firstly, it is necessary to mix the mortar evenly. The mixed material is fed into the hopper of the sprayer through a vibrating screen. Material transportation: The material is moved by a feeder and injected into the direct feeding chamber of the rotor body. As the rotor rotates, the material is transported to the discharge port.

Compressed air introduction: At the discharge port, compressed air is introduced from the air chamber to blow the material into the discharge elbow. Here, the cyclone introduces another stream of compressed air, causing the material to be dispersed, accelerated, and rotated into the conveying pipe in a multi head wind spiral state.

Spray: The material reaches the nozzle through the feeding pipe, and a small amount of supplementary water or liquid quick setting agent is added at the nozzle, and then sprayed out evenly onto the surface of the substrate.

In order to ensure the normal operation and construction quality of the mortar coating machine, the following preparations need to be made before starting up: Check all connecting components of the whole machine: ensure that all connecting components are firm, and that all rotating and sliding parts are flexible and reliable.

Check the rotation direction of the motor: The drive motor is connected to the power supply, and the rotation direction of the rotating body should be consistent with the arrow direction when inching the motor. Otherwise, the power supply should be phase adjusted.

Close the air and water circuits: Place the main air circuit, upper air circuit, lower air circuit, vibrator air circuit, and nozzle water supply shut-off valve in the closed state, connect the main air pipe to the air source, connect the water supply pipeline to the water source, and connect the feeding pipe to the main engine.

Adjust the clamping mechanism: First manually pre tighten, then use a wrench to tighten 2-3 turns, bend the feeding pipe, open the main and upper air circuit shut-off valves, and observe that there is no gas overflow at the rubber joint plate when the pressure gauge is around 0.3Mpa.

Open the air and water paths: First, open the main air path, upper air path, and lower air path shut-off valves of the mortar spraying machine, open the water supply shut-off valve of the nozzle, and pre wet the surface of the rock mass.

Start the motor: Start the motor, open the vibrator air circuit shut-off valve, add the mixture to the hopper, and start the spraying operation. Adjust the water supply of the nozzle: During operation, the nozzle operator should adjust the water supply of the nozzle appropriately to ensure that the concrete material has a suitable water cement ratio.

Through the above steps, the mortar coating machine can efficiently and uniformly apply mortar to the surface of the substrate, improving construction efficiency and quality.

Vertical Delivery Distance

| 4m

|

|---|

Hopper Volume

| 30L

|

Operating Type

| Continuous Operating

|

Transport Package

| Wooden Case

|

Product Name

| Good Quality Mortar Wall Polishing Plaster

|

Material Processed

| Chemicals, Construction,Wall

|

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

Certification

Client's Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.

![[Demo Data]The Top Modern Holiday Gifts for the Design Lover in Your Life2](http://holuo.cn-gd.ufileos.com/hkcms/static/module/index/default/img/new2.jpg)