Small Scale Semi Automatic Soap Set

Production Introduction

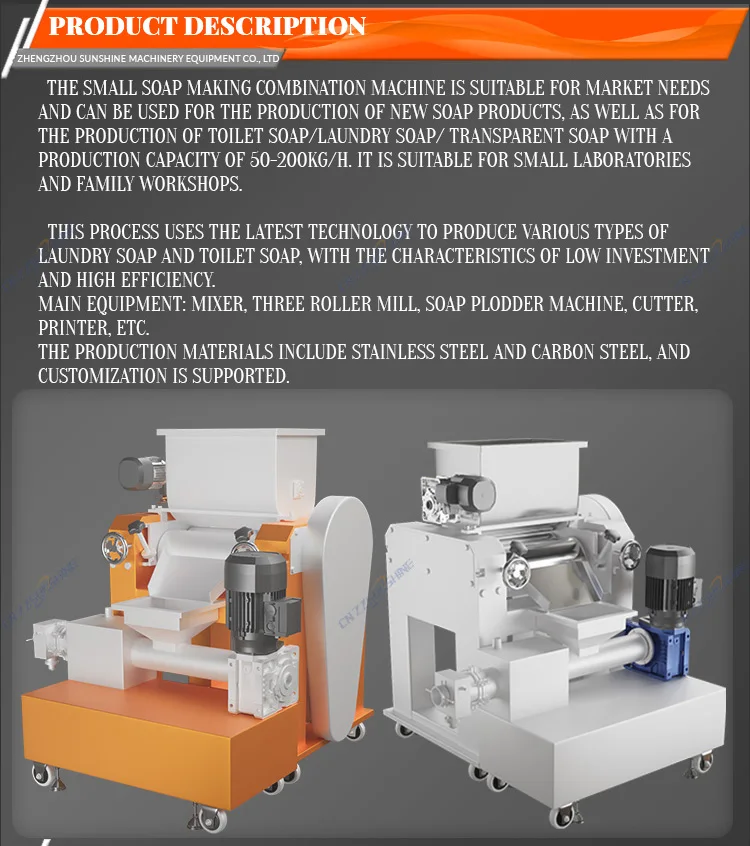

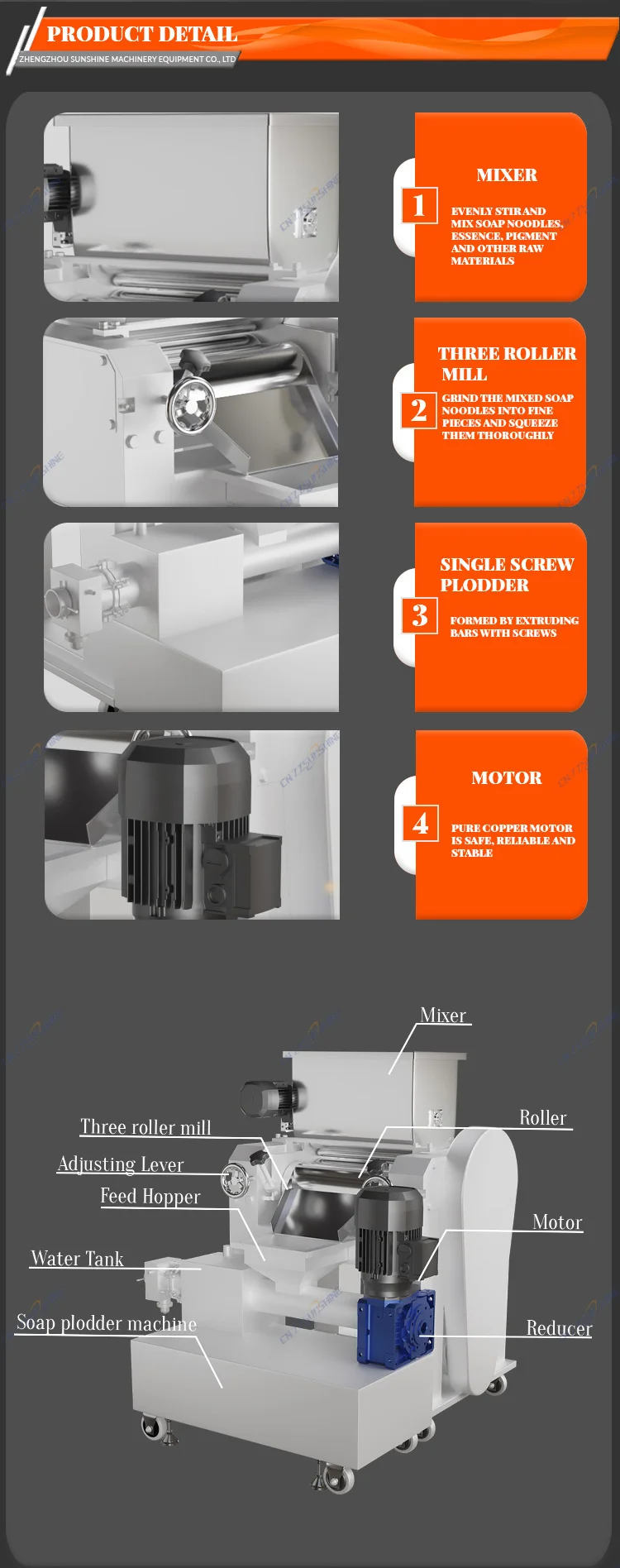

The small-scale soap making combination machine meets market demand and can be used for the production of new soap products, as well as for the production of soap/laundry soap/transparent, with a production capacity of 50-200 kg/h. Suitable for small laboratories and home workshops. This process adopts the latest technology to produce various types of laundry soap/soap, which has the characteristics of low investment and high efficiency.

Main equipment: mixer, three roll grinder, strip mill, chiller; Can be paired with semi-automatic fully automatic cutting machines, semi-automatic printers, etc. for production.The production materials include stainless steel and carbon steel, and support customization.

Safety precautions for use:

1. Upon receiving the machine, check for any loose parts.Add lubricating oil to the gear parts of each component to avoid dry grinding.

2. Before starting up, please check whether there are any foreign objects in the various components of the machine, observe whether there are any friction areas on the mixing blades, three roll grinding rollers, and strip machine screws, and adjust them in a timely manner.

3. Before production, the machine should be idle to check if it runs smoothly.

4. Inject heat transfer oil into the heating chamber of the strip machine, and add sufficient water to the chiller. Before production, the chiller should be turned on first.

5. After production is completed, the machine power should be turned off in sequence and the remaining materials inside each machine should be cleaned to ensure that the machine does not get stuck during the next use.

6. Maintain the machine regularly, check the operation of each part, and timely add lubricating oil to the gear reduction box and each gear part.

Company Information

Certification

Client Feedback

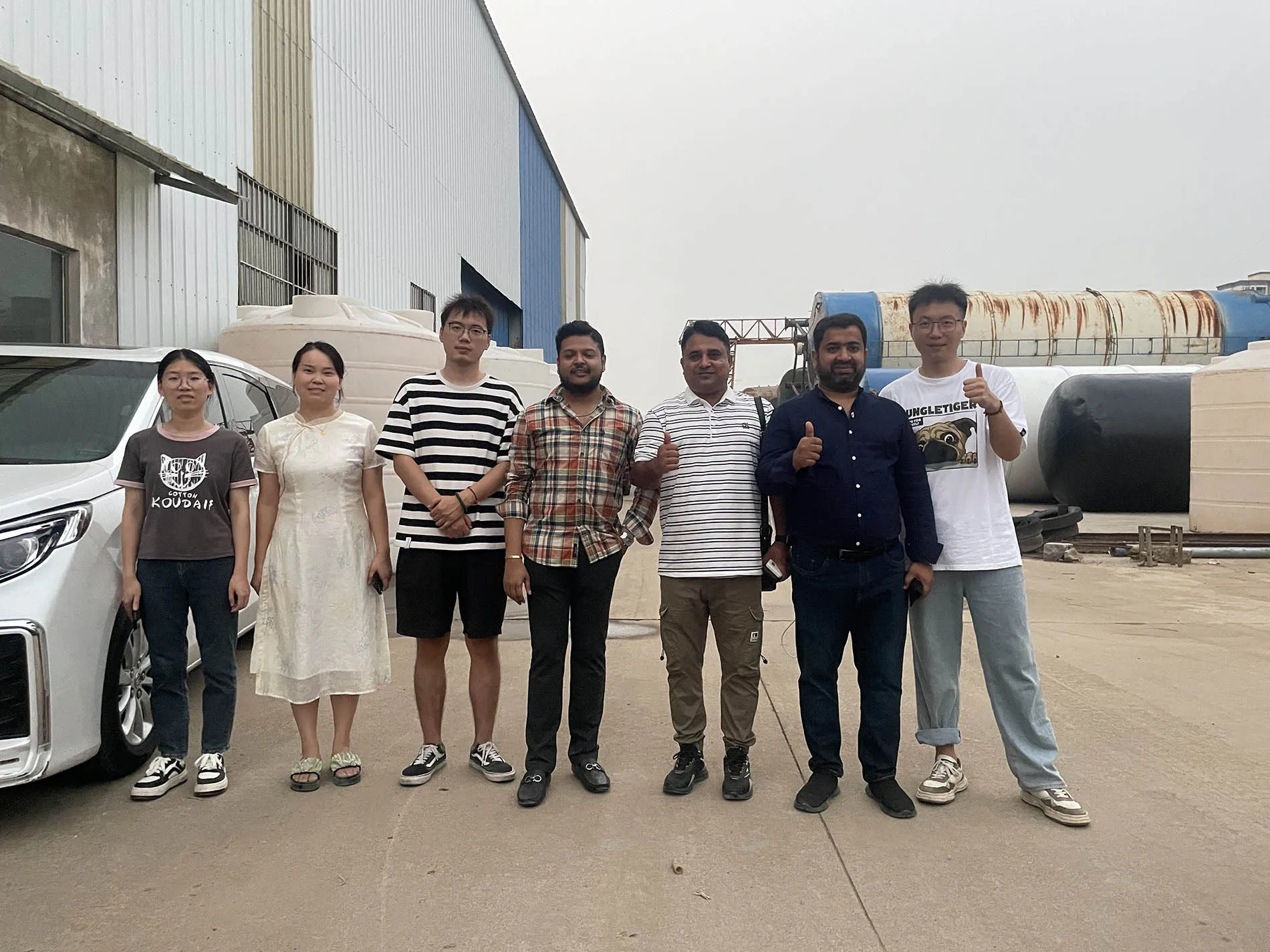

Customer Photos

FAQ

1.Soap production process?

Basically, the soap production need 2 steps:

a, using all kinds of oil/fast as material to produce semi-finished soap noodle;

b, using semi-product soap noodle to produce end bar soap.

2.What is the kinds of the soaps?

For convenience, we separate the soap into two kinds, toilet soap for washing hand&taking bath, herbal soap, hotel soap, antiseptic soap are included;

The second kind is laundry soap for washing clothes, etc.

3.What kind of oil is suitable for soap production?

All kinds of vegetable oil and animal fats are usable, palm oil, cotton seed oil, tallow oil, coconut oil, sunflower oil, etc.

4.What is the formula?

Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market's request is available after confirmation of order.

5. How can we guarantee quality?

We will conduct machine testing before shipment to ensure normal operation and provide videos and manuals.Remote video factory and machine inspections are available, and on-site inspections are welcome.

6.What can you buy from us?

Soap Making Machine,Toilet Soap Production Line,Laundry Soap Making Machine,Packing Machine,Bicolor Soap/Tricolor Soap Production Line,Oil Press Machine

7.Why should you buy from us not from other suppliers?

Zhengzhou Sunshine Machinery Equipment Co,.Ltd is a professional corporation devoted herself to research, development, and manufacturing of all kind of soap machinery and equipment. The corporation owned a creative design and manufacturing team. We have CE certificate, national credit certificate, and factory certification for strength,Welcome to visit our factory.

![[Demo Data]The Top Modern Holiday Gifts for the Design Lover in Your Life2](http://holuo.cn-gd.ufileos.com/hkcms/static/module/index/default/img/new2.jpg)