Machine Introduction

As the name suggests, a "brick making machine" is a mechanical equipment for manufacturing and producing bricks. It generally uses stone powder, fly ash, slag, slag, crushed stone, sand, water, and other materials added with cement as raw materials to produce bricks through hydraulic power, vibration force, pneumatic force, and other mechanical means.

The working principle of the large wheel brick making machine is mainly based on the transmission system of the crank slider mechanism, which realizes the forming process of the brick blank through mechanical motion. Here is a detailed explanation of its working principle:

When the crank rotates upwards, it drives the stamping mechanism of the forming machine to lift upwards.

When the crank rotates downwards, it drives the stamping mechanism of the forming machine to press downwards, and its pressing head automatically presses into the forming mold that has already been filled with the mixture, compacting the waste residue mixture.

Due to the double-sided pressure applied by this molding machine, it can form bricks with high density.

The ejection mechanism under the mold will automatically eject the brick from the mold after it is formed.

After the brick is formed, it can be manually or mechanically transported out of the forming machine. Currently, most devices use mechanical transmission to ensure the safety of operators.

This brick making machine can efficiently press various raw materials into brick blanks through the aforementioned mechanical motion process, making it suitable for large-scale brick production.

Most brick making machines operate in harsh environments such as mud, gravel, rainwater, and wind and snow, and their technical condition will inevitably deteriorate faster than other machinery. The fit between parts will experience varying degrees of looseness, wear, corrosion, and scaling. The fitting properties of various connecting parts, the mutual position relationship between parts, and the coordination of mechanism work will be affected to varying degrees, resulting in a decrease in performance indicators such as power, economy, and reliability, and even causing machine accidents. Therefore, it is necessary to pay attention to the technical maintenance of the unburned brick machine. The technical maintenance of brick making machines refers to a series of technical measures taken to keep the machinery in good technical condition, ensure its reliability, improve work efficiency, and extend its service life. Its main content is focused on cleaning, fastening, lubrication, and adjustment, combined with relevant inspection and testing work.

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

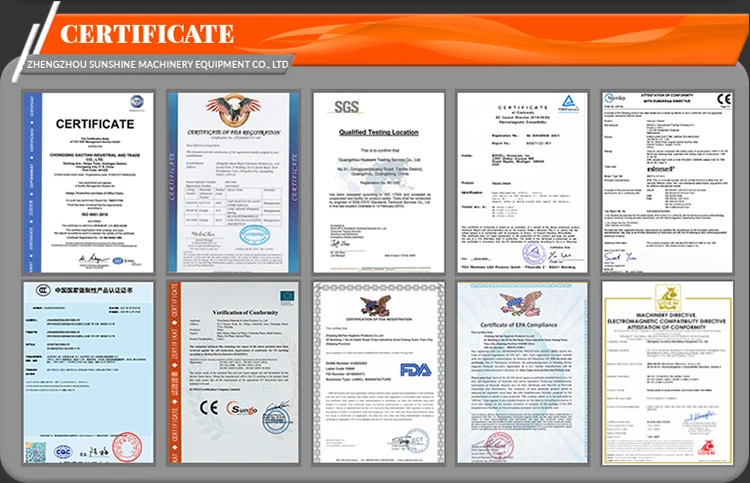

Certification

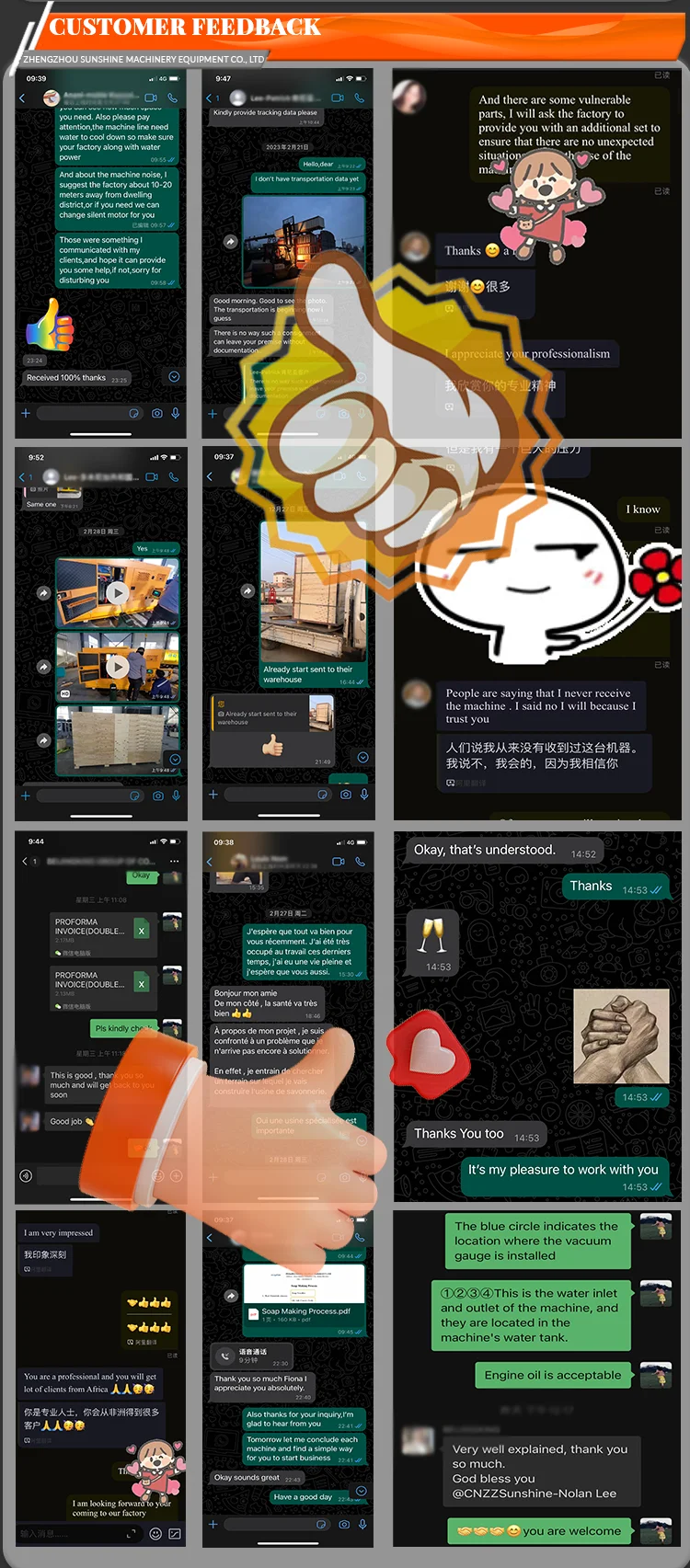

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.

![[Demo Data]The Top Modern Holiday Gifts for the Design Lover in Your Life2](http://holuo.cn-gd.ufileos.com/hkcms/static/module/index/default/img/new2.jpg)