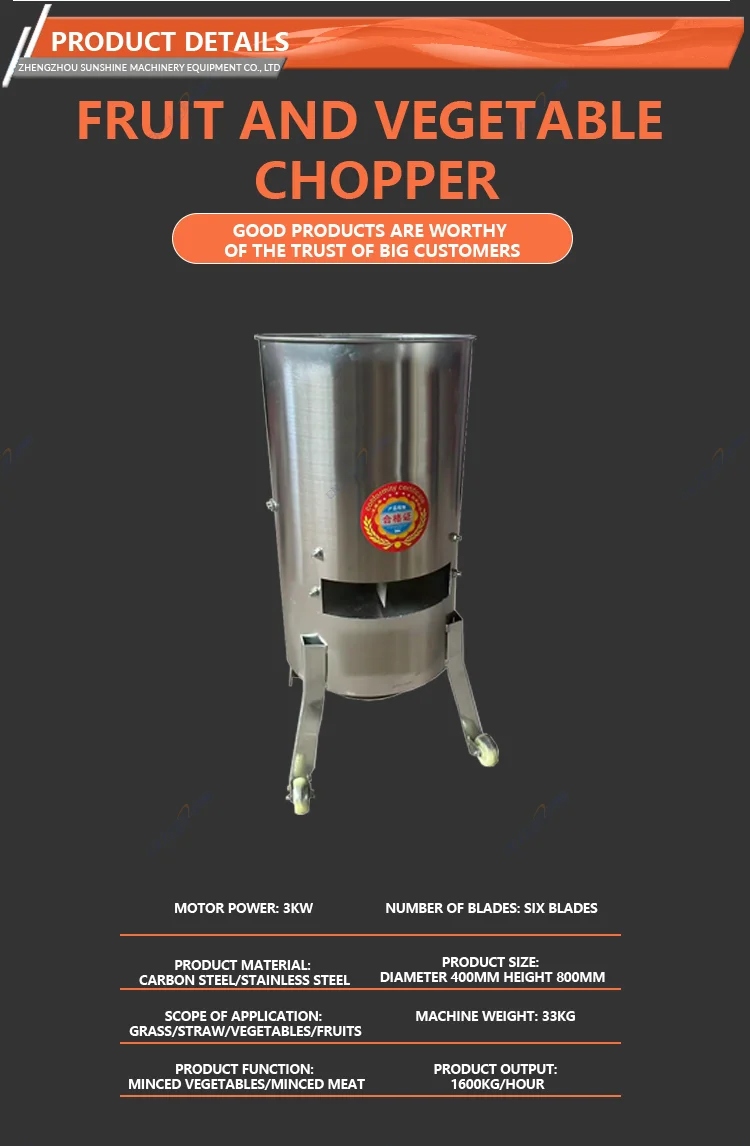

Machine Introduction

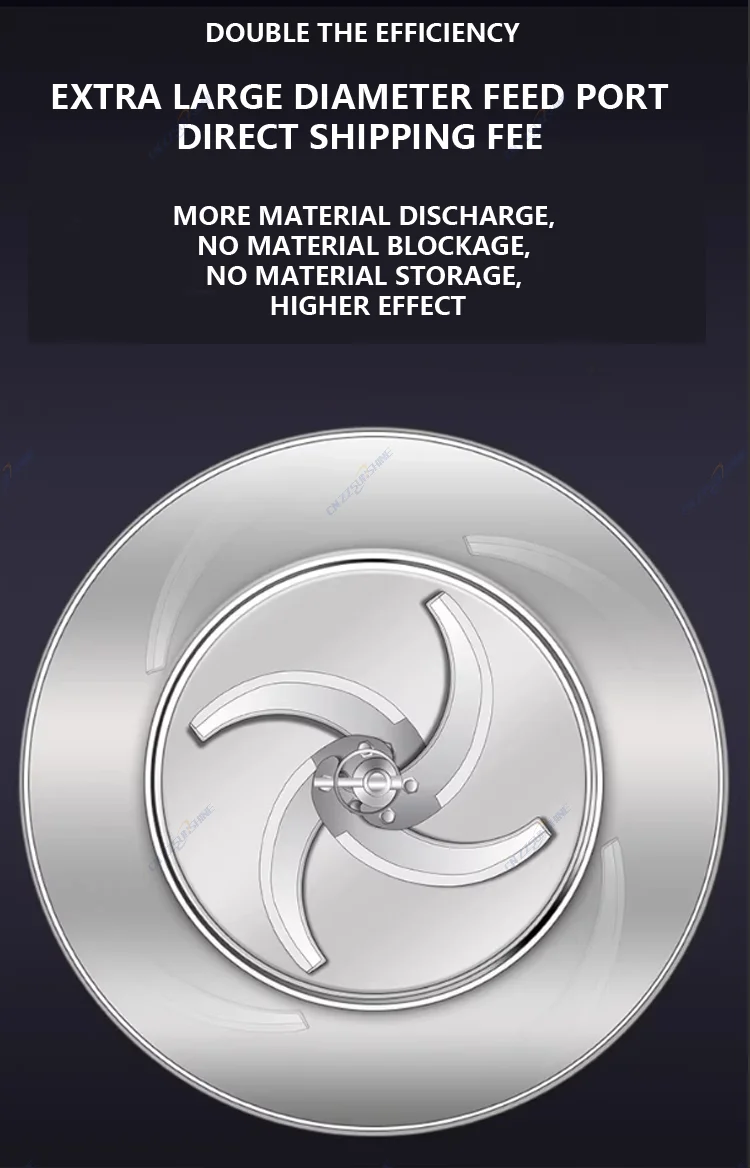

The working principle of the fruit and vegetable slicer is to use a motor to drive the blades to rotate at high speed, generating strong cutting force to quickly divide the ingredients into blocks or slices of the desired size.

The centrifugal slicing mechanism of the vegetable slicer is used for slicing hard vegetables such as melons and potatoes. The slice thickness can be freely adjusted within a certain range, and the vertical blade can process leafy soft vegetables or cut slices into various shapes such as cubes and diamonds of different specifications. The cutting length of vegetables can be adjusted freely within a certain range through an adjustable eccentric wheel. Due to the vertical knife simulating the principle of manual vegetable cutting, the processing surface is smooth and flat, with regular shaping, and the cut vegetables are well-organized and kept fresh.

Before the vegetable slicer starts working, try cutting and observe whether the specifications of the vegetables being cut are consistent with the required specifications. Otherwise, adjust the slice thickness or cutting length to meet the requirements before proceeding normally.

Installation of vertical knife: First, rotate the adjustable eccentric wheel to move the knife holder to the bottom dead center, then lift the knife holder up 1-2 millimeters to make contact with the conveyor belt. Finally, tighten the nut to secure the vertical knife to the knife holder. Explanation: The lifting height of the knife holder can be controlled according to the vegetables being cut. If the lifting height of the knife holder is small, vegetables may be cut together; If the knife holder is lifted too high, it may cut the conveyor belt.

Vegetable slicer adjustment: Rotate the adjustable eccentric wheel, loosen the connecting rod fastening screw, and move the fulcrum for cutting fine threads from the outside to the inside (with the opening facing up at this time). When cutting coarse threads, move the fulcrum from the inside to the outside, and tighten the adjustment screw after adjustment.

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

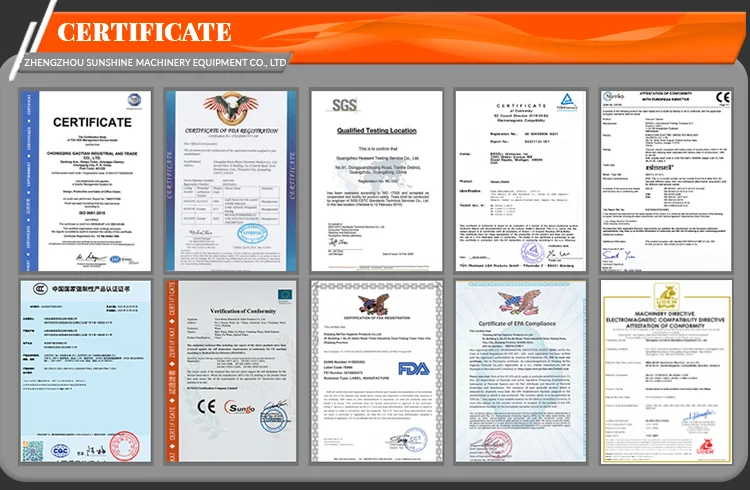

Certification

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.