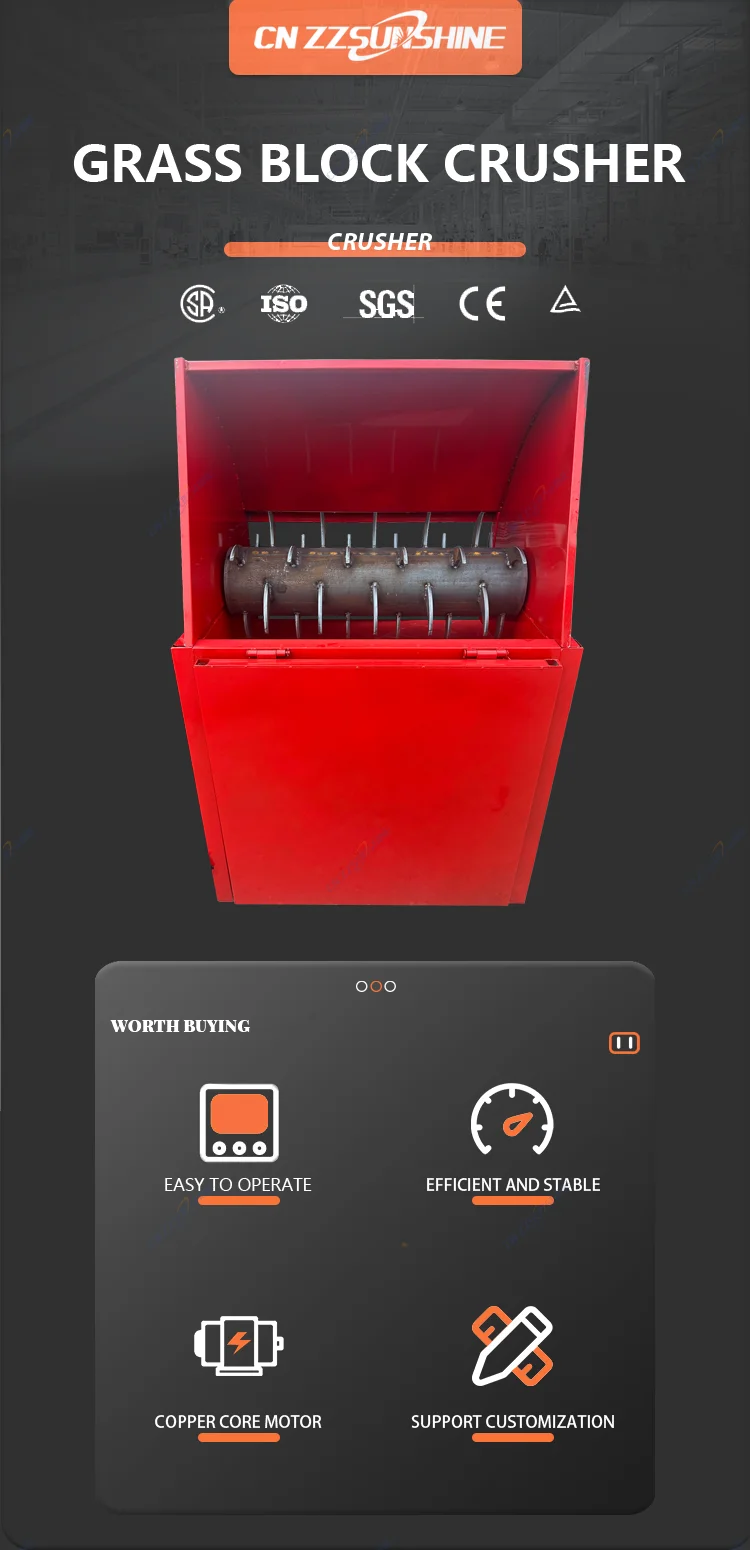

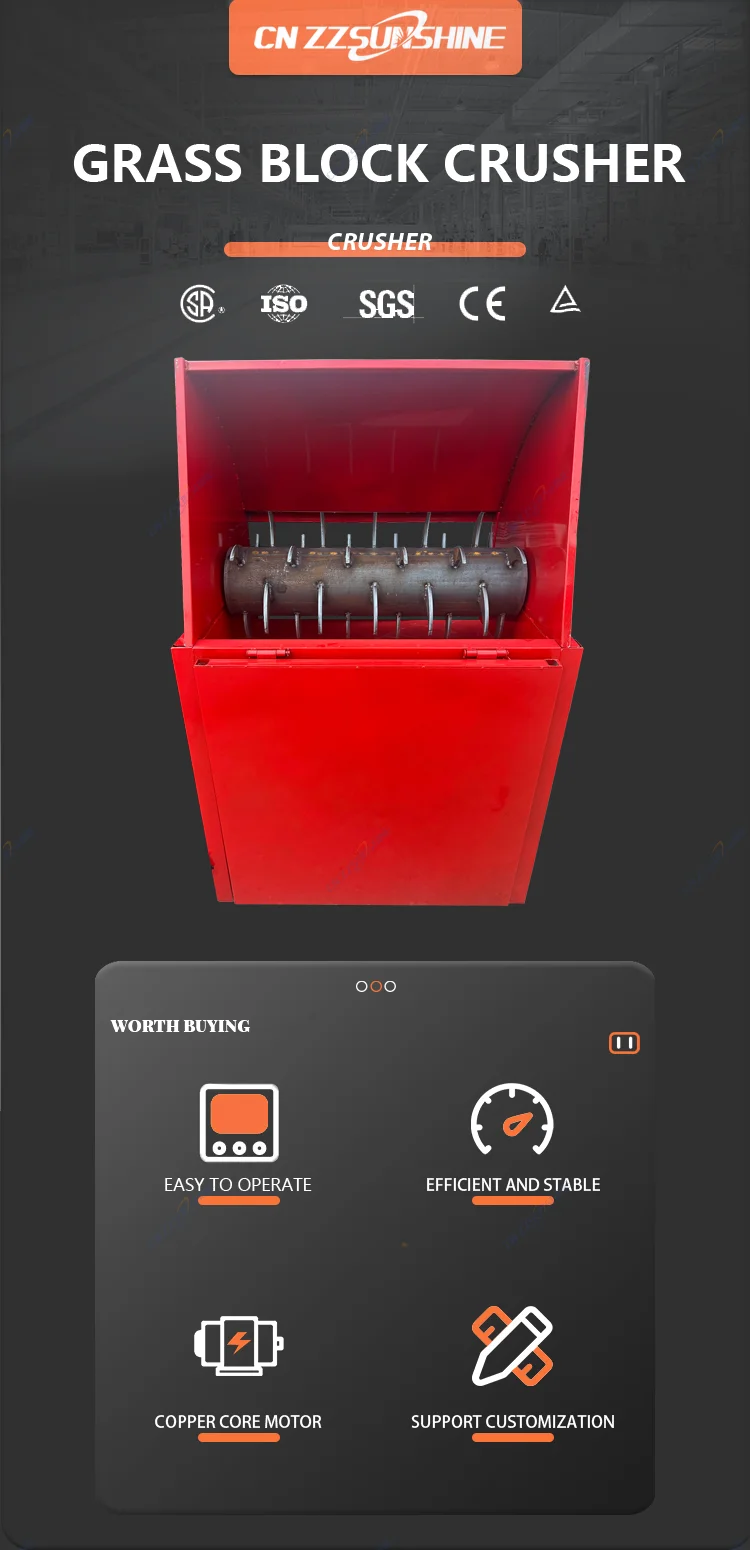

Machine Introduction

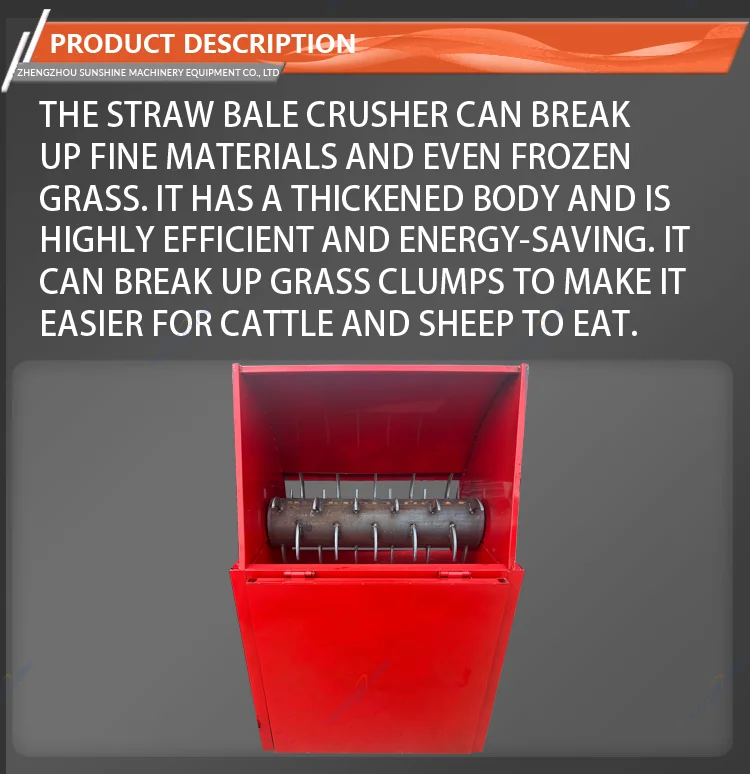

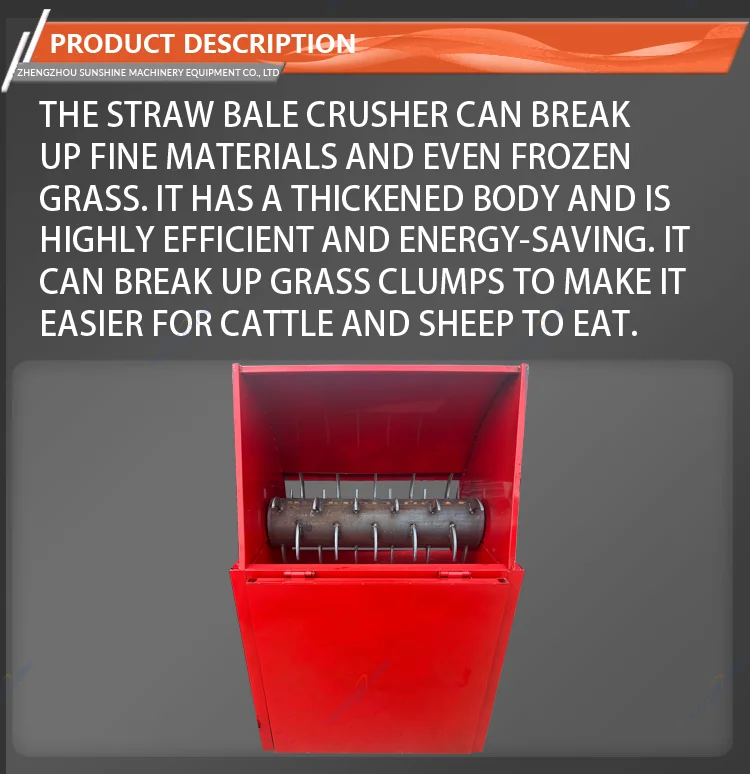

The haystack crusher is mainly used to crush bundled or stacked crop straw and grass such as corn stalks, wheat stalks, peanut seedlings, etc. It can also process biomass such as tree branches and bark. The processed products can be used for power generation, papermaking, feed, organic fertilizer, etc. Its structure usually includes feeding, cutting and throwing, transmission, walking, and protection mechanisms, and has the characteristics of high output, ability to handle dry and wet materials, and easy operation. Attention should be paid to safe operation and regular maintenance during use to ensure the normal operation and safe operation of the equipment.

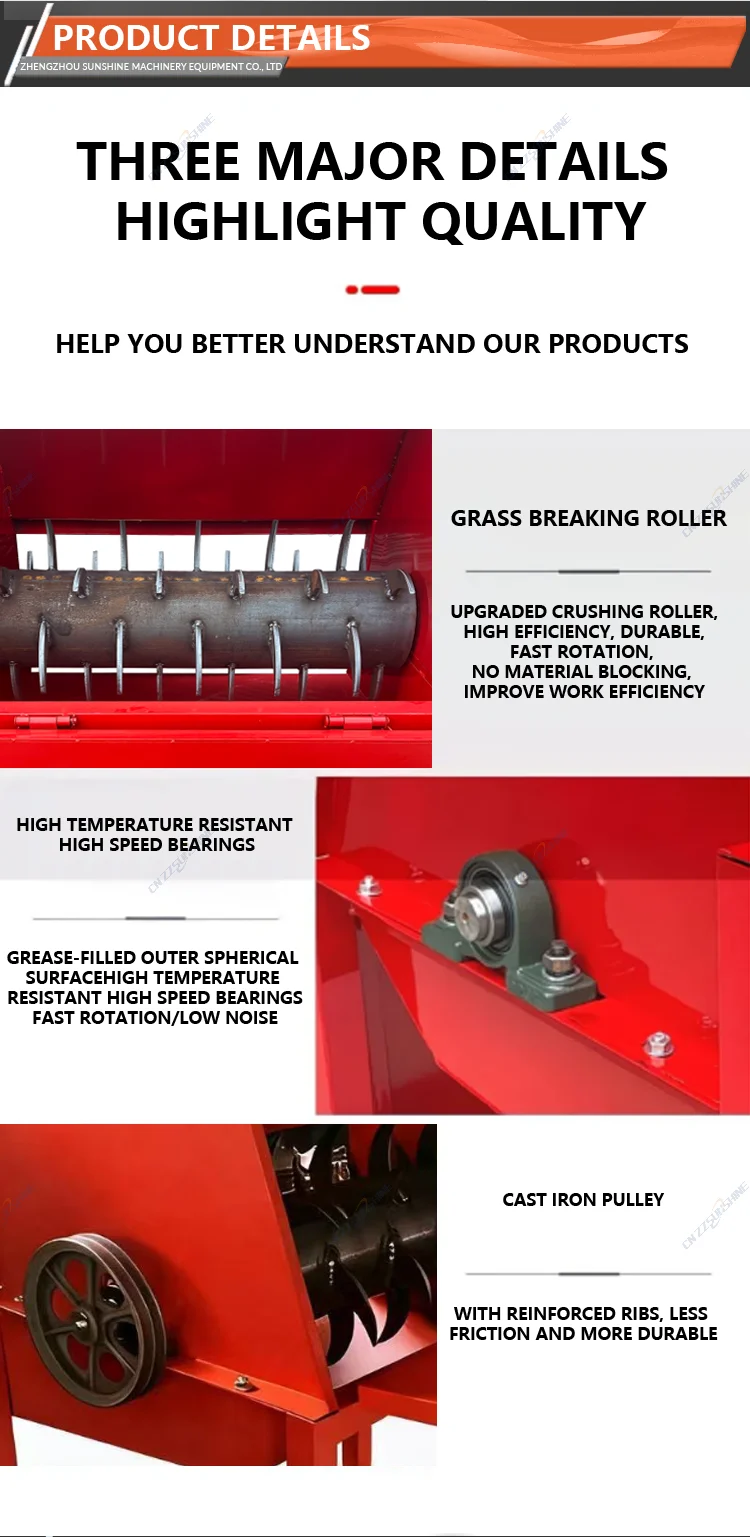

The haystack crusher sends bundled materials into the rotary cutting chamber through the feeding device, and uses high-speed rotating blades (or hammers) to strike and shear the materials. With the help of sieve plates to control the fineness, the crushed materials are sent to a separator (such as a shaker) by centrifugal force or fan, and the air is separated before discharging the finished product.

The operation process of the haystack crusher is divided into preparation, start-up, operation, and shutdown maintenance stages

Preparation stage: Install the unit firmly, check the rotation direction of the motor, the clearance between the moving and fixed blades (≤ 0.8mm), and the fasteners, and test run for 3-5 minutes.

Start up phase: No load start. After confirming that there are no abnormalities, feed evenly to avoid the mixing of hard objects such as metal and stones.

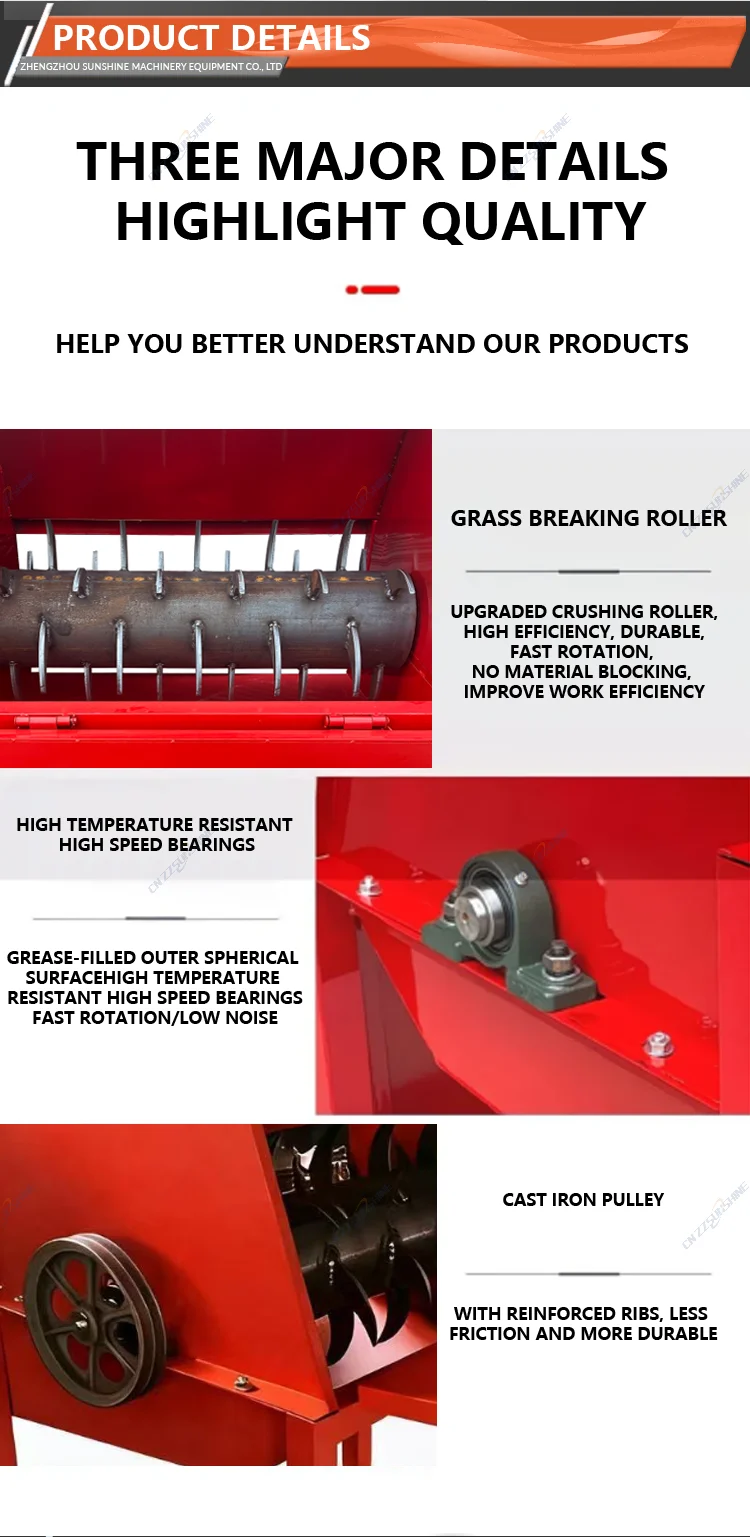

Homework stage: Crushing the haystack with a grass cutter roller, secondary crushing with the grass cutter, adjusting the screen mesh to control particle size, and observing whether the equipment has any abnormal noise or looseness.

Shutdown maintenance: Stop the material first, idle for 5-20 minutes before shutting down, clean up residual materials, regularly check the hammer blades and bearings, and add lubricating oil.

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

Certification

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.